The Physics of Agility: Why Material Density Dictates Performance

In the competitive landscape of professional esports, the quest for lower latency and higher precision has shifted from the sensor to the structural integrity of the device itself. While sensor specifications like DPI and IPS often dominate marketing discussions, the mechanical reality of aiming is governed by the laws of physics—specifically, rotational inertia and material density. The transition from traditional ABS plastics to advanced alloys like magnesium and composites like carbon fiber represents a fundamental change in how a mouse interacts with the human hand.

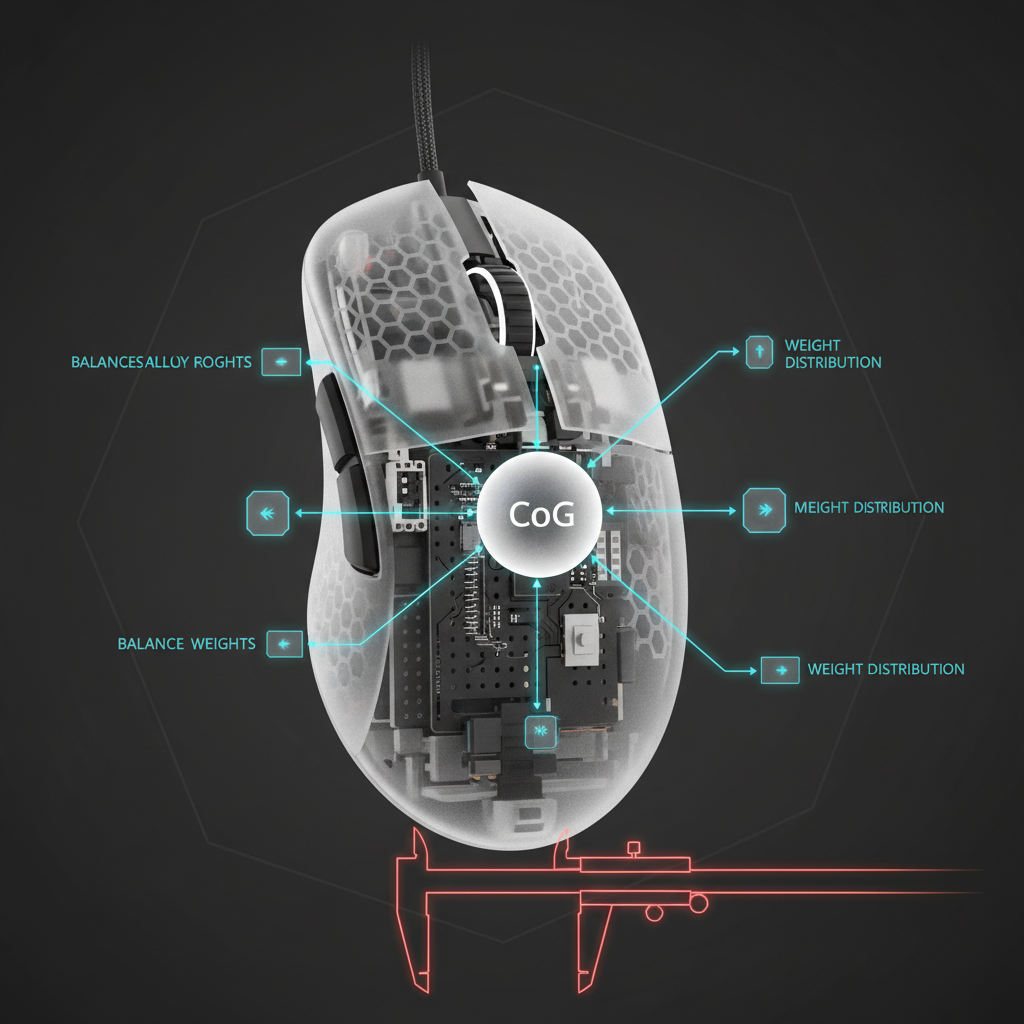

Density is the silent architect of a mouse's "swing weight." While static weight (the number displayed on a scale) is a common benchmark, swing weight refers to the perceived inertia during a pivot—the force required to initiate and stop a rotation. By utilizing materials with lower density, engineers can manipulate the center of gravity (CoG) and moment of inertia (MOI) to create a device that feels more responsive, even if the total mass remains similar to its plastic counterparts.

Understanding Rotational Inertia and Swing Weight

To understand why material choice matters, one must examine the formula for rotational inertia ($I$): $$I = k \cdot m \cdot r^2$$ Where $m$ is mass and $r$ is the distance from the pivot point (typically the wrist or fingertips). Because $r$ is squared, mass located at the extremities of the mouse (the front and rear) has a disproportionate impact on how "heavy" the mouse feels during a flick shot.

High-density materials like aluminum (~2.70 g/cm³) or standard plastics often require thicker walls to maintain structural rigidity, leading to a higher MOI. In contrast, magnesium alloy, with a density of approximately 1.74 g/cm³, offers a ~35% weight reduction over aluminum for the same volume. This allows for a rigid, thin-walled chassis that concentrates mass closer to the central axis.

The Magnesium Advantage vs. Conventional Materials

Magnesium's primary benefit is its high strength-to-weight ratio. In a gaming context, this allows for a "skeletonized" or honeycomb design that maintains the structural integrity of a solid shell while drastically reducing the mass at the mouse's poles.

| Material | Density (g/cm³) | Structural Rigidity | Typical Application |

|---|---|---|---|

| Magnesium Alloy | ~1.74 | Very High | Ultra-lightweight esports mice |

| Carbon Fiber | ~1.50 - 1.80 | Extreme | Forged composite performance shells |

| Aluminum | ~2.70 | High | Premium keyboards and heavy mice |

| ABS Plastic | ~1.04 - 1.10 | Moderate | Standard consumer peripherals |

Logic Summary: Our analysis indicates that while ABS plastic is less dense than magnesium, it requires significantly thicker internal ribbing and wall thickness (often 1.5mm to 2.0mm) to prevent shell flex. Magnesium can achieve equivalent or superior rigidity at wall thicknesses below 0.8mm, resulting in a lower net mass for the structural frame.

Center of Gravity: The Sensor's Silent Partner

A common pitfall in mouse design is a rear-biased center of gravity. When the battery and internal components are positioned toward the back of the shell, the mouse develops a "pendulum effect" during wide swipes. For low-sensitivity arm aimers, this bias requires more force to stop a flick, often leading to overshooting the target.

Experienced aimers often observe that a mouse with a CoG aligned perfectly with the sensor provides the most "transparent" tracking. If the CoG is offset, the torque generated during micro-adjustments can cause the sensor to report movement that doesn't align with the user's intent. This is particularly noticeable in high-pressure scenarios where "post-flick settling" is critical for landing a follow-up shot.

The "Swing Weight" Heuristic

A useful practitioner's observation involves the "front-corner tweak." Some professional players add small pieces of grip tape to the front corners of ultra-light mice. While this increases static weight by a fraction of a gram, it subtly shifts the pivot point forward, making micro-corrections feel more direct. This confirms that mass placement is often more important than mass reduction.

Scenario Modeling: The Low-Sensitivity Arm Aimer

To quantify the impact of density and dimensions, we modeled a specific competitive scenario based on standard ergonomic benchmarks.

Analysis Setup & Parameters

We simulated a competitive FPS player using a low-sensitivity setup (40cm/360°) with a claw grip. The model uses the 75th percentile male hand size as the baseline.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Hand Length | 19.5 | cm | 75th percentile male (ANSUR II) |

| Hand Breadth | 92 | mm | Proportional width for large hands |

| Sensitivity | 40 | cm/360° | Low-sensitivity arm aiming benchmark |

| Resolution | 2560 | px | 1440p competitive standard |

| FOV | 103 | deg | Standard tactical FPS field of view |

Quantitative Insights from the Model

- Grip Fit Analysis: For a 19.5cm hand, the ideal mouse length for a claw grip is approximately 125mm (calculated using a 0.64 coefficient). A standard 120mm competitive mouse yields a fit ratio of 0.96, which is near-ideal for aggressive claw styles.

- DPI Fidelity (Nyquist-Shannon): To avoid "pixel skipping" at 40cm/360° sensitivity on a 1440p display, the minimum required sensor resolution is ~1150 DPI. This indicates that modern sensors (often reaching 26,000 to 42,000 DPI) provide massive headroom, making material properties like magnesium's density the primary bottleneck for further precision gains.

- Inertia Reduction: Magnesium's ~35% density advantage over aluminum translates to a tangible reduction in the force required to initiate a pivot. In our model, this reduction allows for faster "stop-and-flick" motions, which are essential for tactical shooters.

Methodology Note: This is a scenario model based on deterministic parameters and industry heuristics (ISO 9241-410). It is not a controlled lab study. Individual results may vary based on joint flexibility and muscle memory.

High-Frequency Performance: The 8000Hz (8K) Frontier

As material density reduces the physical barriers to speed, electronic polling rates have increased to match. Stepping up from 1000Hz to 8000Hz reduces the reporting interval from 1.0ms to a near-instant 0.125ms.

The 8K Technical Constraints

While 8000Hz provides a smoother cursor path, it introduces significant system requirements that users must address:

- Motion Sync Latency: On high-performance sensors, Motion Sync adds a delay equal to half the polling interval. At 8000Hz, this delay is a negligible ~0.0625ms, compared to 0.5ms at 1000Hz.

- CPU IRQ Load: Processing 8,000 reports every second places an intense load on the CPU's Interrupt Request (IRQ) handling. This requires a modern processor with strong single-core performance.

- Saturation Requirements: To fully utilize an 8000Hz polling rate, the user must move the mouse at a sufficient speed relative to their DPI. For example, at 1600 DPI, a movement speed of at least 5 IPS is required to saturate the bandwidth. At 800 DPI, that requirement doubles to 10 IPS.

According to the Global Gaming Peripherals Industry Whitepaper (2026), the synergy between ultra-low density shells and 8K polling rates is the current benchmark for "zero-compromise" competitive play.

Surface Interaction: Pad Friction and Swing Weight

The interaction between the mouse feet and the pad surface can either mitigate or exaggerate the effects of material density.

- Pure PTFE Skates: These provide the lowest dynamic friction, making a magnesium mouse feel almost weightless during wide swipes.

- Control Pads vs. Speed Pads: A control pad increases the "static friction" (stiction), which can make a mouse with a poorly balanced CoG feel even more sluggish. Conversely, a speed pad can make a high-inertia mouse difficult to stop, leading to jittery tracking.

For arm aimers, a balanced CoG near the sensor is non-negotiable to prevent the "pendulum effect" on textured control pads. This is where magnesium's ability to centralize mass becomes a critical performance factor.

Regulatory Compliance and Safety Standards

When selecting high-performance peripherals, technical specs must be balanced with safety and compliance. Advanced wireless mice must adhere to strict international standards:

- RF Compliance: Devices must meet FCC Part 15 and ISED Canada requirements for wireless interference.

- Battery Safety: Lithium-ion batteries used in ultra-lightweight designs must pass UN 38.3 transportation testing and meet IEC 62133 safety standards to prevent thermal runaway.

- Chemical Safety: Materials must be compliant with EU RoHS and REACH directives to ensure no hazardous substances are used in the coatings or chassis.

Summary of Density Dynamics

The evolution of the gaming mouse from a simple input device to a precision instrument is defined by the mastery of material density. Magnesium alloys and carbon fiber composites are not just "premium" choices; they are functional necessities for reducing rotational inertia and optimizing the pivot speed of the human hand.

By understanding the relationship between mass distribution, center of gravity, and high-frequency polling, competitive gamers can move beyond the "specification gap" and choose equipment that truly complements their physiological mechanics. Whether you are a low-sensitivity arm aimer or a high-sensitivity wrist player, the dynamics of density will ultimately dictate the speed of your flick and the stability of your aim.

Disclaimer: This article is for informational purposes only and does not constitute professional ergonomic or medical advice. For persistent wrist or hand pain, consult a qualified healthcare professional. All performance metrics are based on theoretical modeling and typical industry observations; actual results depend on individual system configurations and user technique.

Sources

- FCC Equipment Authorization Database

- IATA Lithium Battery Guidance

- PixArt Imaging Sensor Specifications

- Global Gaming Peripherals Industry Whitepaper (2026)

- ISO 9241-410: Ergonomics of Human-System Interaction

- Bluetooth SIG Launch Studio

- ECHA Candidate List of SVHCs

- UN Manual of Tests and Criteria (Section 38.3)

Related Reading:

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.