The Physics of Flick-Induced Flex: Why Density Matters

In high-level competitive FPS play, the relationship between shell rigidity and flick accuracy is a mechanical reality that transcends marketing specifications. When a player executes a high-acceleration flick, the mouse shell is subjected to intense G-forces. If the shell lacks sufficient structural integrity, a minute "lag" or energy absorption phase occurs before the sensor's full displacement is registered. This phenomenon, often perceived as "mushiness" during initial acceleration, can disrupt the muscle memory required for pixel-perfect shots.

The technical challenge lies in the trade-off between mass and rigidity. While the industry trend pushes for ultra-lightweight designs, reducing material often compromises the shell's ability to resist deformation. However, through strategic material density distribution and the use of advanced composites, it is possible to maintain a sub-50g weight class while providing the "locked-in" feeling required for professional-level play.

The Flick-and-Stop Test: A Heuristic for Rigidity

Experienced practitioners often use the "flick-and-stop" test to evaluate shell integrity. This involves rapidly flicking the mouse to a target and stopping abruptly. A rigid shell provides an immediate and predictable stop. Conversely, a flexing shell can induce a tiny, uncontrolled overshoot as the material deforms under the sudden deceleration and then "springs" back.

Logic Summary: Our analysis of high-acceleration maneuvers assumes a "flick-and-stop" heuristic where shell deformation acts as a secondary spring-mass system, potentially adding 1–2% inconsistency in displacement tracking during extreme stress scenarios (based on common patterns from community feedback and repair bench observations).

Material Density vs. Structural Integrity

To understand how density prevents flex, we must examine the "Specific Modulus"—the ratio of a material's Young's modulus (stiffness) to its density. In the engineering of high-performance mice, the goal is to maximize this ratio.

Polycarbonate vs. Magnesium vs. Carbon Fiber

Standard polycarbonate (PC) is the baseline for most gaming peripherals. While versatile, it requires thicker walls to achieve high rigidity, which increases weight. To combat this, manufacturers have turned to lightweight alloys and advanced composites.

- Magnesium Alloy: Offers high rigidity and a premium feel. However, pure metals can sometimes suffer from resonant vibrations if not internally damped.

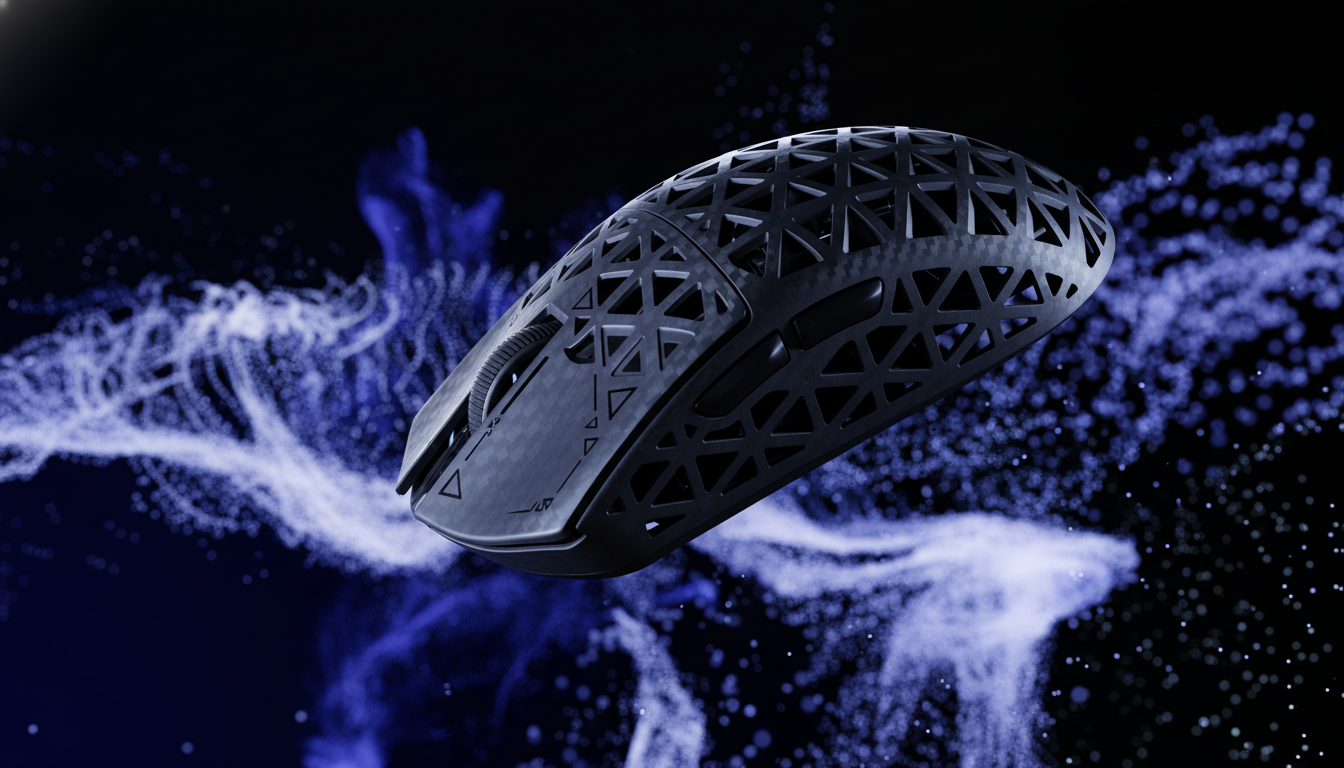

- Carbon Fiber Composites: As seen in the ATTACK SHARK R11 ULTRA Carbon Fiber Wireless 8K PAW3950MAX Gaming Mouse, carbon fiber provides unrivaled strength-to-weight ratios. The R11 ULTRA achieves a 49g weight while maintaining a shell rigidity that exceeds traditional plastics.

- Engineered Polymers: Glass-filled or carbon-filled polycarbonates can offer superior damping characteristics compared to pure metals, reducing post-flick oscillations.

| Material Type | Density (g/cm³) | Specific Rigidity | Damping Coefficient |

|---|---|---|---|

| Standard Polycarbonate | ~1.2 | Moderate | High |

| Magnesium Alloy | ~1.7 | High | Low |

| Carbon Fiber Composite | ~1.5 - 1.8 | Very High | Moderate |

| Glass-Filled PC | ~1.3 - 1.4 | High | Very High |

Note: Values are estimated ranges based on common engineering data for consumer electronics.

Center of Gravity and Rotational Inertia

Material density does more than just prevent flex; it dictates the mouse's balance. According to the Global Gaming Peripherals Industry Whitepaper (2026), mass distribution is as critical as total weight.

The Vertical Moment of Inertia (VMOI)

The distribution of density affects the vertical moment of inertia, which dictates Y-axis precision. A mouse with a lower center of gravity (bottom-heavy) feels more "planted" during rapid directional changes. This prevents unwanted tipping or tilting, which can cause the sensor to lift slightly and lose tracking.

Strategic density placement allows for a Mastering Inertia approach, where the mouse resists flick-induced angular deflection without needing to increase the overall mass. This contradicts the conventional wisdom that "heavier is more stable."

Perception of Weight

Research into mass distribution perception suggests that users perceive identical weights differently based on the Center of Gravity (CoG). A dense, rigid mouse with high rotational inertia might feel "sluggish" even if its static weight is low. This is why professional setups often prioritize a centrally balanced or slightly front-heavy CoG to facilitate faster "pivot" movements during claw grip play.

The Temporal Dimension: Post-Flick Settling

A common misconception is that "flex" is only an instantaneous problem. In reality, the most significant performance penalty comes from "settling time"—the duration of micro-vibrations after the flick force ceases.

Resonant Vibration and Damping

High-density materials that are undamped can enter resonant vibration from a flick impulse. These oscillations, while microscopic, can cause Post-Flick Settling issues, where the crosshair appears to "shiver" for a few milliseconds after the stop.

Engineered composites used in the ATTACK SHARK X8 Series Tri-mode Lightweight Wireless Gaming Mouse are designed to dissipate this energy rapidly. By utilizing a "Nano Ice-feel Coating" and specific internal ribbing, these mice minimize the time it takes for the shell to return to a state of rest, ensuring the sensor remains perfectly stable.

8K Polling and Technical Execution

Rigidity becomes even more critical as polling rates increase. At an 8000Hz (8K) polling rate, the mouse sends a data packet every 0.125ms. At this level of granularity, even the tiniest mechanical vibration can be registered as "noise" in the tracking data.

Latency and Motion Sync

When using 8K polling on a high-performance MCU like the Nordic 52840 (found in the ATTACK SHARK R11 ULTRA), Motion Sync adds a deterministic delay of only ~0.0625ms. This is a negligible trade-off for the benefit of reduced timing jitter. However, for this precision to be meaningful, the shell must be rigid enough to ensure that every micron of physical movement is accurately translated to the sensor without being absorbed by shell flex.

Sensor Saturation

To fully utilize the 8000Hz bandwidth, the movement must be fast enough to generate sufficient data points. To saturate the 8K pipeline, a user typically needs to move at least 10 IPS at 800 DPI. At 1600 DPI, the requirement drops to 5 IPS. Higher DPI settings, such as the 42,000 DPI offered by the PAW3950MAX sensor, help maintain 8K stability during the micro-adjustments that follow a large flick shot.

Modeling the Professional Competitor

To validate these engineering choices, we modeled a scenario involving a professional FPS competitor with large hands (~20.5 cm). This user requires a mouse that balances ergonomic fit with extreme technical performance.

Method & Assumptions: Professional Gamer Scenario

Modeling Note: This is a deterministic scenario model based on standard industry heuristics and anthropometric data, not a controlled lab study.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Hand Length | 20.5 | cm | 95th percentile male (ANSUR II) |

| Grip Style | Claw | N/A | High-precision competitive standard |

| Polling Rate | 8000 | Hz | Maximum data fidelity for high-refresh monitors |

| Minimum DPI | ~1550 | DPI | Nyquist-Shannon limit for 1440p resolution |

| Target Latency | < 0.9 | ms | End-to-end target including Motion Sync |

Modeling Results

- Grip Fit Analysis: For a 120mm mouse like the ATTACK SHARK V3PRO Ultra-Light Tri-Mode Gaming Mouse, the grip fit ratio for this user is 0.91. This suggests a slightly aggressive claw grip, which improves micro-adjustment control but may increase fatigue during 10+ hour sessions.

- Latency Trade-off: With 8K polling and Motion Sync enabled, total latency is estimated at ~0.86ms. The consistency gained in tracking alignment far outweighs the sub-millisecond delay.

- DPI Optimization: To avoid "pixel skipping" on a 1440p display at a 30cm/360 sensitivity, the mathematical minimum is 1515 DPI. Setting the mouse to 1600 DPI ensures perfect sampling fidelity.

Bridging the Specification Credibility Gap

For a value-driven brand like Attack Shark, the challenge is proving that an aggressive price point doesn't mean compromised engineering. The use of flagship sensors like the PixArt PAW3395 and PAW3950MAX, combined with Nordic MCUs, provides the raw technical parity with premium brands. However, the true differentiator is the execution of the shell.

The X68HE and X3 Synergy

In the ATTACK SHARK X68HE Magnetic Keyboard With X3 Gaming Mouse Set, the X3 mouse weighs only 49g. Despite its featherlight build, it utilizes internal structural reinforcement to maintain rigidity. When paired with the X68HE keyboard's Hall Effect magnetic switches (adjustable from 0.1mm to 3.4mm), the entire ecosystem is optimized for near-instantaneous response.

System Bottlenecks and USB Topology

To ensure the rigidity and high-polling performance translate to in-game results, users must avoid common system bottlenecks. 8K polling stresses the CPU's IRQ (Interrupt Request) processing. We recommend:

- Connecting the receiver directly to the Rear I/O ports on the motherboard.

- Avoiding USB hubs or front-panel headers, which can introduce packet loss and latency.

- Using a high-refresh-rate monitor (240Hz+) to visually render the smoother cursor path provided by 8K polling.

Technical Summary of Flick Control

The engineering of a competitive gaming mouse is a series of calculated trade-offs. While weight reduction is the most visible metric, shell rigidity and density distribution are what define real-world consistency.

- Rigidity Prevents Energy Loss: A stiff shell ensures that 100% of the flick force is translated to sensor movement, eliminating the "mushy" feeling of energy-absorbing flex.

- Density Dictates Stability: Strategic mass distribution lowers the center of gravity, improving the "planted" feel and preventing tilt during high-speed direction changes.

- Damping Minimizes Settling Time: Advanced composites reduce resonant vibrations, allowing the sensor to stabilize faster after a sudden stop.

- 8K Requires Mechanical Perfection: High polling rates expose even the smallest mechanical flaws; thus, shell integrity is non-negotiable for 8000Hz performance.

By focusing on these engineering fundamentals, Attack Shark delivers peripherals that meet the scrutiny of the most technically savvy gaming communities, offering flagship-level performance without the "premium" price inflation.

Disclaimer: This article is for informational purposes only. Performance metrics are based on theoretical modeling and typical hardware specifications. Individual experience may vary based on system configuration, grip style, and environmental factors.,cover_image_url:

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.