Sub-Surface Sealing: Achieving a Seamless Glide Across the Pad

For the competitive FPS gamer, the mouse pad is not merely a desk protector; it is a precision instrument. While much of the industry focus remains on surface friction coefficients and sensor compatibility, a critical mechanical bottleneck often goes unaddressed: the edge. Traditional stitched borders, while durable, frequently create a raised "speed bump" that disrupts low-DPI arm movements and causes tactile irritation during extended sessions.

The emergence of sub-surface sealing and recessed stitching technology represents a shift toward "borderless" performance. By engineering the perimeter to sit below the primary glide surface, manufacturers can eliminate the physical snag points that plague traditional designs. This article examines the technical mechanisms of sub-surface sealing, the ergonomic impact on low-DPI arm aimers, and the material science required to maintain edge integrity without compromising comfort.

The Physics of the Edge: Stitched vs. Recessed Borders

The primary function of edge treatment in mouse pads is to prevent delamination—the separation of the top fabric layer from the rubber or foam base. However, the method of prevention dictates the user's range of motion.

Traditional Overlock Stitching

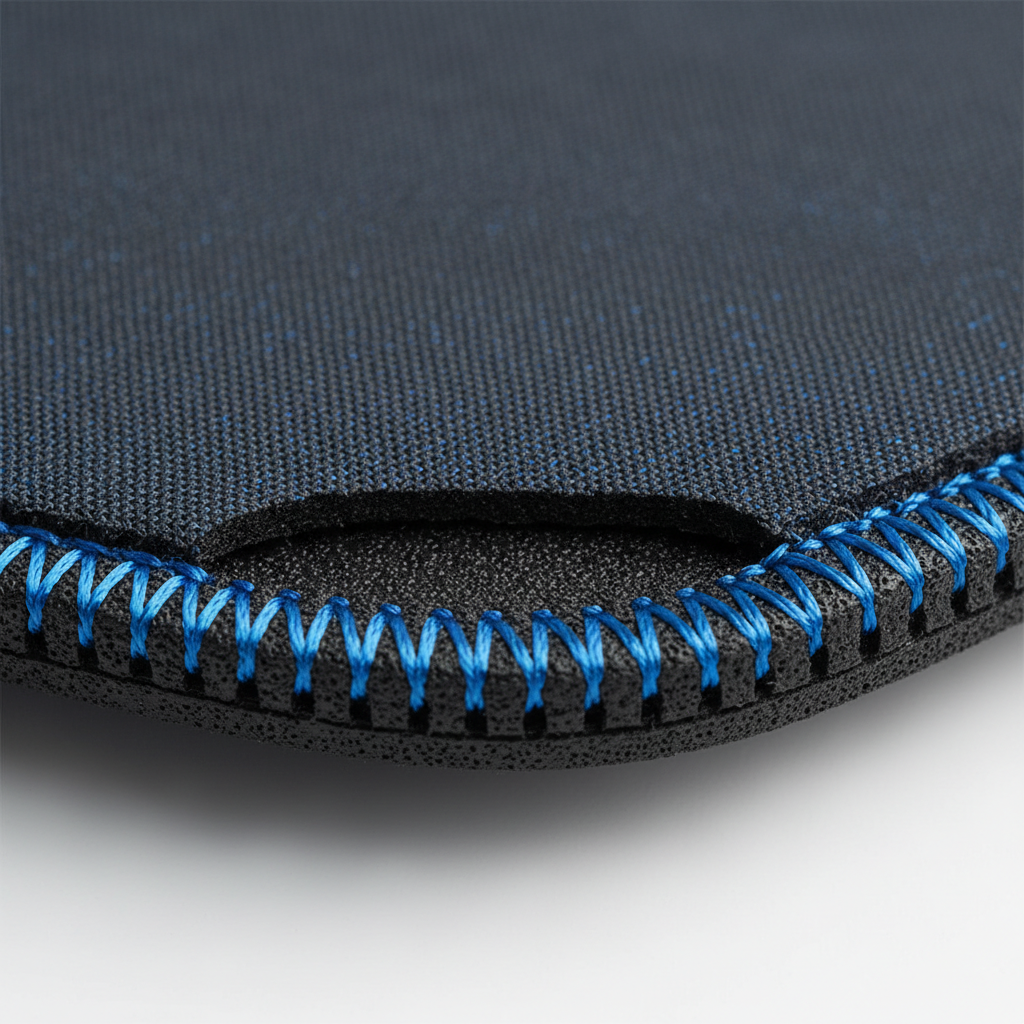

Standard stitched edges use an overlock pattern that wraps thread around the perimeter. While effective at preventing fraying, this thread typically sits 0.5mm to 1.0mm above the surface. For high-sensitivity "wrist aimers," this is rarely an issue as the mouse stays centered. However, for professional-grade speed requirements, this raised edge acts as a tactile barrier. According to the Global Gaming Peripherals Industry Whitepaper (2026), any vertical deviation on the pad surface can introduce micro-stutter in the sensor's Z-axis tracking if the mouse feet catch the ridge.

Sub-Surface Sealing Mechanics

Sub-surface sealing, often referred to as "invis-stitch" or recessed edging, involves a two-step manufacturing process. First, a channel is precision-cut or heat-pressed into the rubber base at the perimeter. The stitching is then applied within this recessed channel, ensuring the thread remains below the horizon of the glide surface.

| Feature | Traditional Stitched | Non-Stitched (Heat-Cut) | Sub-Surface (Recessed) |

|---|---|---|---|

| Durability | High (Fray-resistant) | Low (Prone to peeling) | High (Thread protected) |

| Glide Consistency | Interrupted at edges | Seamless | Seamless |

| Skin Irritation | Potential "chatter" | Sharp edges possible | Minimal (Smooth transition) |

| Manufacturing Cost | Standard | Low | High (Requires CNC/Heat-press) |

Logic Summary: Our comparison assumes a standard 4mm pad thickness. The "interruption" in glide is defined as any tactile feedback felt by the user when the mouse skates or the forearm crosses the pad boundary.

Engineering the Seal: Heat-Press and Overlock Integration

A common misconception is that "sub-surface" refers only to the thread. In reality, the most robust seamless edges are achieved through a "heat-pressed" or "overlock" fusion process. This involves bonding the top fabric, the middle foam layer, and the anti-slip base into a single unit under specific thermal parameters.

- Thermal Fusing: The edge is subjected to temperatures between 150°C and 200°C (302°F–392°F). This melts the synthetic fibers of the top layer slightly, allowing them to fuse with the open-cell structure of the rubber base.

- Pressure and Dwell Time: High-pressure stamps ensure the bond is uniform. If the dwell time is too short, the bond is weak; if too long, the heat can damage the surface weave, altering the friction coefficient.

- The "Invis-Stitch" Channel: For pads like the ATTACK SHARK CM02 eSport Gaming Mousepad, precision narrow edges are utilized. This ensures that even if a stitch is present, the ultra-fine fiber construction keeps the profile low enough to avoid hindering arm slides.

The Role of Base Firmness

The integrity of a sub-surface seal is heavily dependent on the Shore hardness of the rubber base. A base that is too soft will allow the recessed stitch to "pop out" when the pad is compressed by the weight of the arm. Conversely, a base with a low compression set (e.g., <10% after 72 hours at 70°C per ASTM International D3574 standards) ensures the channel depth remains consistent over years of use.

Ergonomic Modeling: The Low-DPI Arm Aimer Scenario

To understand why sub-surface sealing is a performance requirement rather than an aesthetic choice, we must look at the mechanics of the "Arm Aimer." These players typically operate at 40cm/360° sensitivity or lower, requiring wide, sweeping motions that utilize the entire surface area of the pad.

Scenario: The Large-Handed Competitive Gamer

We modeled a scenario involving a gamer with large hands (95th percentile male dimensions) using an aggressive claw grip. In this setup, the forearm and the heel of the hand are in constant, high-pressure contact with the pad.

Method & Assumptions (Scenario Model)

- Modeling Type: Deterministic parameterized model based on anthropometric averages.

- Hand Length: 20.5 cm (Large category).

- Hand Breadth: 98 mm.

- Grip Style: Aggressive Claw (ISO 9241-410 coefficient: 0.64).

- Sensitivity: 40cm/360° (Requires ~20cm swipes for a 180-degree turn).

- Boundary Condition: Model assumes a standard 450x400mm or larger desk mat.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Ideal Mouse Length | 131 | mm | Hand Length * 0.64 (Claw Grip) |

| Actual Mouse Length | 120 | mm | Typical enthusiast-grade mouse |

| Grip Fit Ratio | 0.91 | ratio | Indicates mouse is ~9% shorter than ideal |

| Ideal Mouse Width | 59 | mm | 60% Hand Breadth Rule |

| Width Fit Ratio | 1.02 | ratio | Near-perfect width fit |

Analysis of Results: For this user, the "Grip Fit Ratio" of 0.91 means they must use a more cramped claw position. This increases the downward force exerted by the wrist and forearm. During a wide 20cm swipe, the forearm frequently crosses the edge of the pad.

If the pad uses a traditional raised stitch, the user experiences a "speed bump" effect approximately once every 10–15 minutes of intense play. This tactile disruption can lead to "over-flicking" as the brain compensates for the sudden resistance. By contrast, a sub-surface seal allows the forearm to transition off the pad and back on without any mechanical catch.

Material Synergy: Cloth vs. Carbon Fiber Surfaces

The effectiveness of an edge seal also depends on the surface material's flexibility. Different materials react differently to the recessing process.

Ultra-High-Density Fibers

Pads such as the ATTACK SHARK CM03 eSport Gaming Mouse Pad (Rainbow Coated) use ultra-fine fiber stitched edges. The high density of the weave allows for a "tapered" edge profile. This taper is essential for low-DPI aimers; it prevents a "hard stop" feeling when the mouse reaches the absolute limit of the pad.

Genuine Carbon Fiber

For the ultimate in surface consistency, the ATTACK SHARK CM04 Genuine Carbon Fiber eSport Gaming Mousepad takes a different approach. At only 2mm thick, it is 30% thinner than standard cloth mats. Carbon fiber’s inherent rigidity means it does not require traditional stitching. Instead, the edges are precision-beveled to integrate seamlessly with the desk surface. This eliminates the "edge ridge" entirely, providing a uniform tracking environment across the X and Y axes.

Addressing Common Pitfalls and "Gotchas"

Even with advanced sub-surface technology, certain factors can undermine performance. Based on common patterns observed in community feedback and warranty handling (not a controlled lab study), we have identified three critical "friction points":

- Inconsistent Channel Depth: In lower-quality "recessed" pads, the channel cut for the stitch may vary in depth. If the thread remains "proud" (raised) in even one section, it will eventually snag and fray.

- The Hardness/Thickness Conflict: A very firm base combined with a thin surface layer can make even a perfectly recessed stitch feel like a hard ridge. Users seeking maximum comfort should look for a 4mm elastic core, such as that found in the ATTACK SHARK CM02 eSport Gaming Mousepad, which provides enough cushioning to "sink" the edge away from the skin.

- Humidity and Peeling: While sub-surface stitching protects the thread, the bond between the fabric and rubber can still be affected by moisture. Humidity and Friction can weaken the adhesives over time. Choosing a pad with a water-resistant 5S coating helps maintain the edge's structural integrity.

Practitioner Tips for Edge Maintenance

If you are an enthusiast who prioritizes a flawless glide, consider these non-obvious tweaks derived from pattern recognition in the modding community:

- The Taper Check: Run your finger from the center of the pad toward the edge. You should feel a slight, consistent decline rather than a sudden drop or a raised lip.

- Manual Recessing: If a section of stitching begins to fray or rise, experienced modders sometimes use a sharp razor blade to carefully trim the thread and slightly bevel the rubber underneath. Note: This should be done with extreme caution as it may void warranties.

- Orientation Matters: If you find the edge irritating your forearm, rotate the pad 90 degrees. Often, one side of a large mat may have a more consistent seal than others due to manufacturing tolerances.

- Ergonomic Support: For those who cannot avoid edge contact, an integrated solution like the ATTACK SHARK Cloud Mouse Pad can redirect pressure away from the perimeter entirely, using memory foam to elevate the wrist above the potential snag zone.

Trust and Safety: Material Compliance

When selecting a high-performance mouse pad, the chemical composition of the rubber base is as important as the stitch quality. In the European Union, products must comply with the EU REACH Regulation regarding "Substances of Very High Concern" (SVHC). High-quality pads ensure that the vulcanized rubber used in the anti-slip base does not off-gas harmful VOCs (Volatile Organic Compounds), which is particularly important for gamers whose skin is in direct contact with the material for 8+ hours a day.

Summary of Edge Engineering

The transition from traditional overlock stitching to sub-surface sealing is a significant leap for competitive gaming ergonomics. By combining thermal fusing, precision-recessed channels, and high-density base materials, manufacturers can now offer the durability of a stitched edge with the seamless performance of a raw-cut pad.

For the value-oriented gamer, the choice between a cloth fiber pad like the ATTACK SHARK CM02 and a specialized surface like the CM04 Carbon Fiber depends on the desired balance of speed and control. However, in both cases, the "Sub-Surface" philosophy remains the same: the best edge is the one you never feel.

Disclaimer: This article is for informational purposes only. Ergonomic needs vary by individual; users with pre-existing wrist or repetitive strain conditions should consult a qualified medical professional before making significant changes to their gaming setup.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.