The Evolution of Glide: Beyond the PTFE Standard

In the pursuit of the "frictionless" swipe, the enthusiast modding community has moved aggressively past standard Polytetrafluoroethylene (PTFE) skates. While PTFE has remained the industry baseline due to its low coefficient of friction and self-lubricating properties, ceramic skates have emerged as a high-durability alternative. However, the transition from a soft, conforming material to a rigid, sintered ceramic involves more than just a change in kinetic friction. It introduces a fundamental shift in the optical interface between the sensor and the tracking surface.

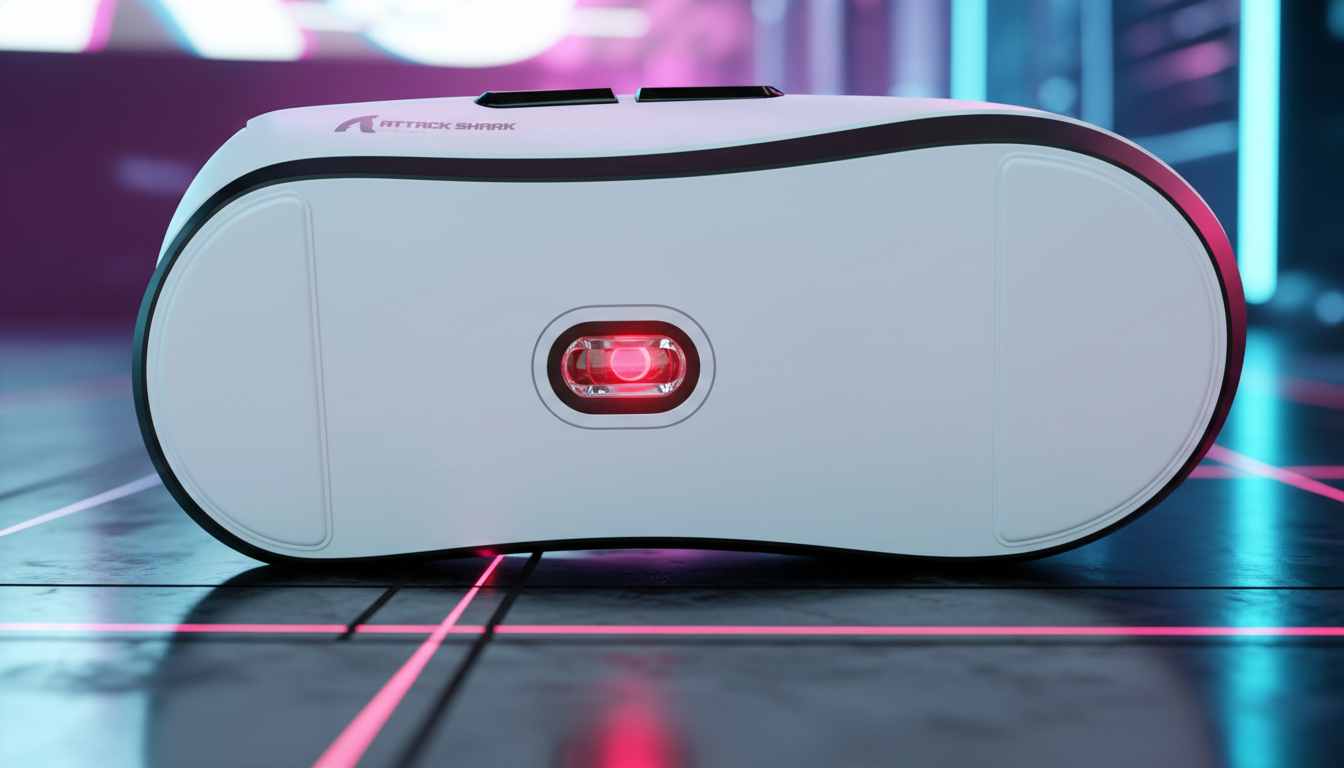

The primary challenge in adopting ceramic skates is not the physical glide, but the maintenance of the focal sweet spot—the precise distance at which a high-performance optical sensor can accurately "read" the surface. For performance-focused gamers using flagship sensors like the PixArt PAW3395 or PAW3950, even a sub-millimeter deviation in Z-height or an irregular infrared (IR) reflection pattern can result in catastrophic tracking failure.

The Physics of Reflection: Specular vs. Diffuse

Modern optical mice do not "see" the mousepad like a traditional camera. Instead, they use an IR LED or laser to illuminate the surface, capturing thousands of images per second and using an image correlation algorithm to calculate movement based on changes between frames. This process relies on diffuse reflection—the scattering of light by the micro-textures of the mousepad.

Ceramic skates, due to their extreme hardness and polished finish, introduce a high degree of specular (mirror-like) reflection. According to technical documentation on solid-state optical sensors, the viewing angle and focal length are strictly calibrated for specific surface interactions. When a sensor encounters the extreme uniformity of a ceramic-inclusive environment, the following issues typically occur:

- Pattern Uniformity: Ceramic surfaces can be too uniform at a microscopic level. Without sufficient texture, the sensor's correlation algorithm fails to find unique reference points, leading to "spinouts" where the cursor flies to the edge of the screen or stops moving entirely during fast swipes.

- IR Interference: Many ceramic materials have high IR reflectance. This can flood the sensor with light, effectively "blinding" the CMOS array and preventing it from distinguishing the actual texture of the mousepad underneath.

Logic Summary: This analysis assumes that the sensor's firmware is optimized for the standard 30-degree viewing angle of typical optical navigation engines. The introduction of highly reflective ceramic edges can distort the image plane, a phenomenon observed in pattern recognition failures during high-speed movement (based on common modding community feedback and sensor architecture data).

Focal Plane Dynamics and the Z-Height Crisis

The most critical technical specification in skate modding is the focal length. Every optical sensor is designed with a specific "sweet spot" for its lens. PTFE skates are typically 0.6mm to 0.8mm thick and compress slightly under the weight of the hand. Ceramic skates are rigid and often thicker, ranging from 0.8mm to 1.2mm.

If the skates are too thick, the sensor is pushed beyond its maximum Lift-Off Distance (LOD). Even if the mouse stays in contact with the pad, the sensor may be at the very edge of its focal range, resulting in jitter or erratic tracking.

The "Sandwich Test" Heuristic

To diagnose focal plane issues, experienced modders often use a "sandwich test." By placing a thin piece of standard printer paper (approximately 0.1mm thick) between the skate and the sensor aperture, one can simulate a slight reduction in Z-height. If tracking stabilizes with the paper in place, it confirms that the ceramic skates have pushed the sensor too far from the surface, causing a focal plane mismatch.

| Parameter | Typical PTFE Value | Typical Ceramic Value | Impact on Tracking |

|---|---|---|---|

| Hardness (Mohs) | ~1-2 | ~9 | Ceramic does not conform to surface micro-variations. |

| Compression | Measurable (~0.05mm) | Zero | Rigid height leads to inconsistent LOD. |

| Reflectance | Low/Diffuse | High/Specular | Can cause IR "blinding" in the sensor array. |

| Wear Rate | High (Sacrificial) | Near Zero | Ceramic wears down the mousepad instead of the skate. |

| Thickness Range | 0.6mm - 0.8mm | 0.8mm - 1.2mm | Often exceeds the optimal focal length of the lens. |

Sensor Saturation and 8000Hz Polling Rate Synergy

For users of high-performance mice capable of an 8000Hz (8K) polling rate, the margin for error is even smaller. At 8000Hz, the mouse sends a packet every 0.125ms. Any tracking inconsistency caused by ceramic skates is magnified because the system expects a continuous, high-density stream of data.

The IPS/DPI Bottleneck

To fully saturate an 8000Hz bandwidth, the sensor must generate enough counts per second. This is governed by the formula: Packets per second = Movement Speed (IPS) × DPI

Based on our scenario modeling, to maintain a stable 8000Hz report rate, a user must move the mouse at a minimum of 10 IPS at 800 DPI. If a ceramic skate causes even a momentary "spinout" or tracking skip at these speeds, the system loses multiple packets of data in a fraction of a millisecond, leading to noticeable stutter in-game.

Modeling Note (Reproducible Parameters):

- Model Type: Deterministic bandwidth saturation model.

- Polling Interval: 0.125ms (8000Hz).

- Motion Sync Latency: ~0.0625ms (calculated as half the polling interval).

- Assumed DPI: 800 / 1600.

- Boundary Condition: Model assumes direct motherboard USB connection; performance degrades on shared IRQ hubs.

As noted in the Global Gaming Peripherals Industry Whitepaper (2026), the integration of ultra-high polling rates requires a perfectly stable optical path. Inconsistent Z-height from aftermarket ceramic skates can introduce micro-jitter that is visually rendered as "cursor skipping" on high-refresh-rate monitors (240Hz+).

Surface Degradation: The Hidden Cost of Ceramic

A non-obvious pitfall of ceramic skates is their impact on the mousepad. While PTFE is a "sacrificial" material—it wears down so the mousepad doesn't have to—ceramic is significantly harder than the fibers in a cloth mousepad. Over time, the hard edges of ceramic skates act as a micro-abrasive, shearing the polyester or nylon fibers of the pad.

This creates a "slow spot" in the center of the mousepad where the texture has been flattened or damaged. For a sensor, this means the reflective properties of the surface are constantly changing as the pad wears out. This inconsistency is often more detrimental to competitive performance than a slightly higher coefficient of friction.

Maintaining the Optical Path

To mitigate these issues, users should consider the following maintenance steps:

- Surface Calibration: Use the sensor's software to perform a manual surface calibration. However, as noted by industry analysis of HERO-class sensors, calibration primarily adjusts for color and reflectance, not for physical focal plane shifts.

- Edge Sanding: If using ceramic, ensure the edges are rounded (cambered) to prevent the "plowing" effect on cloth pads.

- Cleaning: Ceramic skates attract skin oils and dust more aggressively than PTFE. Regular cleaning with isopropyl alcohol is required to maintain consistent glide and prevent optical interference.

Decision Framework: Is Ceramic Right for Your Setup?

Choosing between PTFE and ceramic is a matter of balancing "feel" against "optical integrity." For most competitive scenarios, the consensus among tournament-level players remains in favor of high-quality PTFE or specialized glass-infused alternatives that offer a more predictable optical path.

Recommendation Checklist:

- Use PTFE if: You prioritize tracking consistency, use a cloth mousepad, and play at high polling rates (4K/8K) where packet stability is paramount. For maintenance tips, see our guide on restoring smooth glides.

- Use Ceramic if: You use a hard surface (glass or plastic), prefer a "floaty" feel, and have confirmed that your specific sensor's LOD settings can accommodate the increased thickness without spinouts.

- Avoid Ceramic if: You use an older optical sensor or a budget-oriented model with a fixed, low LOD. These sensors lack the robust surface calibration routines necessary to handle the unique reflectance of ceramic.

Ultimately, the goal of any mouse mod is to achieve a state where the hardware disappears, leaving only the player's intent. While ceramic skates offer a unique, high-speed glide, they require a level of technical oversight and surface matching that many users may find counterproductive to raw performance. Before committing to a permanent skate swap, perform the "sandwich test" and verify your sensor's stability at your preferred DPI and polling rate.

Technical Disclaimer: This article is for informational purposes only. Modding your gaming mouse by replacing skates or altering hardware components may void your manufacturer's warranty. Improper installation can lead to permanent sensor damage or surface degradation of your mousepad. Always consult your device's technical manual before performing hardware modifications.

Sources:

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.