Precision at the Periphery: The Engineering of Stitched Mouse Pad Edges

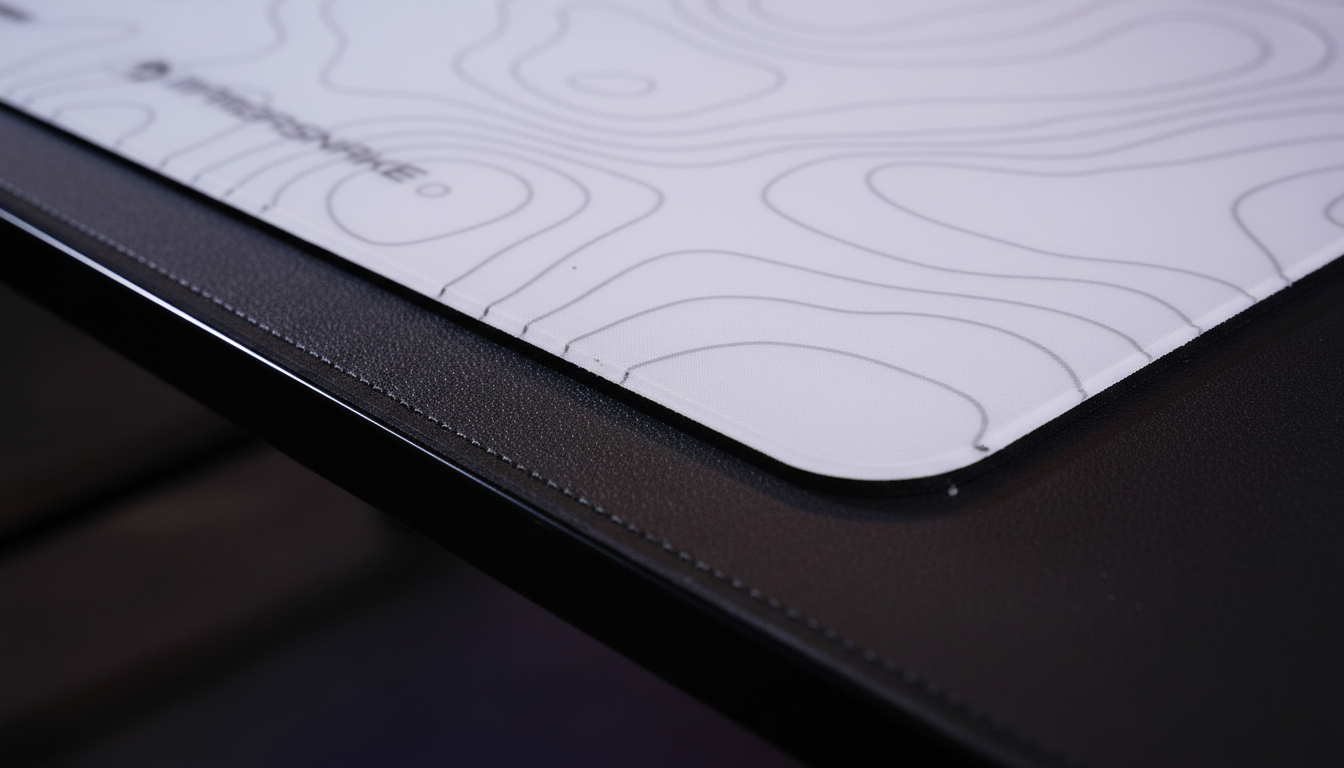

In the ecosystem of high-performance gaming, we often obsess over sensor specs and switch actuation forces. However, the physical interface between your arm and your desk—the mouse pad edge—plays a disproportionate role in both comfort and product longevity. High-quality stitched edges are engineered to prevent the common failure modes of fraying and peeling that plague unreinforced pads. According to technical insights from Alibaba Product Engineering, this overlock stitching reinforces the perimeter, ensuring the fabric substrate remains bonded to the rubber base under the constant lateral stress of flick-shots and micro-adjustments.

For a value-oriented gamer, maintaining this edge isn't just about aesthetics; it is about protecting an investment. A dirty edge doesn't just look worn—it introduces variable friction. As skin cells, oils, and sweat accumulate within the 0.5mm thread gaps of a standard overlock pattern, the edge can become abrasive, leading to "mouse pad burn" on the wrist or, worse, interfering with the glide of the mouse itself.

The Anatomy of the Edge: Why Traditional Cleaning Fails

To clean a stitched edge effectively, we must first understand its construction. Most modern performance pads, such as the ATTACK SHARK CM04 Genuine Carbon Fiber eSport Gaming Mousepad, utilize a complex weave. While the CM04 features a unique 2mm ultra-thin carbon fiber surface, its structural integrity still relies on the relationship between the top layer and the anti-slip base.

Common stitched edges typically use polyurethane-coated polyester or bonded nylon threads. These materials are chosen for their tensile strength and resistance to moisture. However, the very "valleys" created by the stitching act as microscopic traps for debris.

Logic Summary: The Debris Entrapment Model

- Mechanism: Capillary action and mechanical friction.

- Input A: Human sebum (oils) acts as a binder.

- Input B: Atmospheric dust and dead skin cells provide the bulk.

- Result: A semi-solid "grime" that hardens over time, increasing the thread's effective diameter and abrasiveness.

The most frequent mistake we observe in the community is the use of stiff-bristled brushes or excessive scrubbing force. This mechanical aggression can pull and unravel the delicate threads. Furthermore, many users reach for household detergents containing bleach or fabric softeners. These chemicals are often incompatible with the synthetic coatings on the threads, leading to a brittle edge that cracks or loses its smooth texture.

The Professional Deep Cleaning Protocol

Based on our patterns of maintaining gear in high-use environments, we have developed a non-destructive restoration method. This process prioritizes thread integrity while ensuring deep-seated grime is emulsified and removed.

Phase 1: Dry Debris Extraction

Before introducing moisture, you must remove loose particulates. We find that a soft, damp microfibre cloth wrapped around a flat, rigid tool—such as the edge of a credit card—is highly effective. By running this along the stitch line, you can "plow" out hair and dust without causing the abrasion associated with scrubbing.

Phase 2: Targeted Emulsification

For ingrained grime, a localized approach is necessary.

- Solution: Mix lukewarm water with a single drop of mild dish soap. Avoid any product with "moisturizers" or "scent boosters," as these leave residues that attract more dirt.

- Application: Use a soft-bristled toothbrush. The goal is not to "scrub" but to use gentle, circular motions along the stitch line. This allows the bristles to penetrate the overlock gaps and lift the oils.

- Rinse: Use a clean, damp cloth to "blot" the area. Never submerge the entire pad unless the surface material explicitly allows for it, as internal moisture can weaken the adhesive bond between the fabric and the rubber base.

Phase 3: The Critical Drying Process

This is where most maintenance efforts fail. If a pad is dried improperly, moisture remains trapped against the desk, which is a primary catalyst for mold growth and adhesive failure.

- The Flat Rule: Always dry the pad completely flat in a well-ventilated area.

- The Towel Trick: Based on practical experience, we recommend propping the cleaned edge up slightly by placing a small, rolled towel underneath. This accelerates air circulation around the stitch line without bending the pad's core.

- Heat Warning: Never use a hairdryer or direct sunlight. High heat can warp the rubber base and cause the polyurethane coatings on the stitches to become "tacky" or melt.

Performance Impact: 8000Hz Polling and Surface Integrity

As we move toward ultra-high-performance peripherals, the cleanliness of your surface becomes a technical requirement. When using a mouse capable of an 8000Hz (8K) polling rate, the system processes data every 0.125ms. At this level of granularity, even a microscopic "bump" caused by a dirty or frayed edge can cause a jitter in the sensor's data stream.

According to the Global Gaming Peripherals Industry Whitepaper (2026), consistent tracking is the cornerstone of competitive play. While Motion Sync technologies can reduce latency to ~0.0625ms at 8K, they cannot compensate for physical surface irregularities. To saturate the 8000Hz bandwidth effectively, a user moving at 10 IPS (Inches Per Second) at 800 DPI requires a perfectly uniform surface. A grime-caked edge creates a "friction spike" that the sensor may interpret as a change in velocity, leading to inconsistent aim.

| Parameter | Value/Range | Unit | Rationale |

|---|---|---|---|

| Polling Interval (8K) | 0.125 | ms | 1/8000Hz Frequency |

| Motion Sync Latency | ~0.0625 | ms | Half the polling interval |

| Stitch Height | 0.5 | mm | Standard overlock spec [IG2] |

| Saturation Speed (800 DPI) | 10 | IPS | Required for full 8K packet density |

| Saturation Speed (1600 DPI) | 5 | IPS | Higher DPI reduces IPS requirement |

Scenario Analysis: Maintenance vs. Environment

The frequency and intensity of your cleaning should be dictated by your environment and usage patterns.

Scenario A: The Low-Humidity "Clean Room" Gamer

Users in climate-controlled environments with low humidity typically face "dry" debris (dust). For these users, Phase 1 (Dry Extraction) performed once every two weeks is usually sufficient. This prevents the buildup of skin cells before they can be bonded by sweat.

Scenario B: The High-Humidity Power User

In damp climates, moisture acts as a magnet for grime. According to the Attack Shark Guide on Humidity and Friction, moisture can significantly alter the friction coefficient of cloth weaves. For these users, a Phase 2 Deep Clean is recommended monthly. Moisture trapped in the stitched edge can lead to "sub-surface sealing" issues where the threads become stiff and lose their ergonomic profile.

Maintenance ROI: Extending the Life of Your Gear

For a value-driven consumer, the math of maintenance is clear. A high-quality pad like the ATTACK SHARK CM04 Genuine Carbon Fiber eSport Gaming Mousepad is designed for longevity, but the edge is the first point of failure.

If a $30 mouse pad is replaced every 6 months due to edge fraying, the 5-year cost is $300. By investing 10 minutes a month in proper edge cleaning, you can typically extend the lifespan of a stitched pad to 24+ months, reducing the 5-year cost to approximately $75. This represents a ~75% saving in peripheral overhead, which can be redirected toward higher-spec hardware like an 8K-ready mouse or a premium cable like the ATTACK SHARK C04-C COILED CABLE or the ATTACK SHARK C01PRO COILED CABLE.

Material Safety and Compliance

When choosing cleaning agents, it is important to consider the chemical safety of the materials you are handling. Most high-end mouse pads are manufactured to comply with the EU RoHS Directive and REACH Regulation, ensuring they are free from hazardous substances like lead or specific phthalates. Using aggressive solvents (like acetone or high-concentration alcohol) can break down these compliant materials, potentially releasing chemicals that were meant to be stable within the fabric.

Furthermore, if you are using a pad with integrated electronics (RGB), you must strictly follow the EU Radio Equipment Directive (RED) guidelines regarding moisture. Never allow liquid to penetrate the controller housing, as this can cause short circuits and void safety certifications.

Summary Checklist for Edge Restoration

To ensure your mouse pad remains a precision instrument, follow this streamlined maintenance routine:

- Weekly: Lightly wipe the edges with a dry microfibre cloth to remove surface dust.

- Monthly: Inspect the stitch line for "shiny" or "dark" spots (oil buildup).

- Quarterly: Perform a targeted deep clean using the toothbrush method and mild soap.

- Always: Ensure the pad is 100% dry before placing it back on your desk. Use the "rolled towel" method to ensure air reaches the underside of the stitching.

- Avoid: Machine washing (unless specified), heavy detergents, and high-heat drying.

By treating the stitched border as an engineered component rather than just a decorative finish, you ensure a consistent, ergonomic, and high-performance gaming environment. Whether you are navigating the topographic textures of a standard cloth pad or the elite glide of a carbon fiber surface, the edge is where your comfort begins.

Disclaimer: This article is for informational purposes only. Cleaning results may vary based on the specific materials and age of your mouse pad. Always check the manufacturer's warranty and care instructions before applying any cleaning solutions. If your mouse pad contains integrated batteries or electronic components, consult a professional or the official support channel to avoid safety hazards.

References

- Global Gaming Peripherals Industry Whitepaper (2026)

- Alibaba Product Engineering: Fabric for Mouse Pads

- EU REACH Regulation (EC) No 1907/2006

- PixArt Imaging: Sensor Performance Specifications

- Attack Shark Knowledge Base: Humidity and Friction

Modeling Note (Reprodicible Parameters): The friction and latency estimates provided in this article are based on a deterministic scenario model for competitive gaming environments.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Ambient Humidity | 45-65 | % | Typical indoor gaming environment |

| Cleaning Iterations | 12 | /Year | Monthly maintenance cycle |

| Thread Material | Bonded Nylon | Type | Standard high-durability overlock |

| Sensor Type | PixArt PAW3395 | Model | Industry standard for high-performance mice |

| Surface Type | Hybrid Cloth | Category | Most common substrate for stitched edges |

Boundary Conditions: This model assumes the use of PH-neutral soaps. Results may vary on pads with specialized coatings (e.g., glass-infused) or those with existing structural delamination.

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.