Cordura vs. Polyester: Comparing Weave Durability for Pros

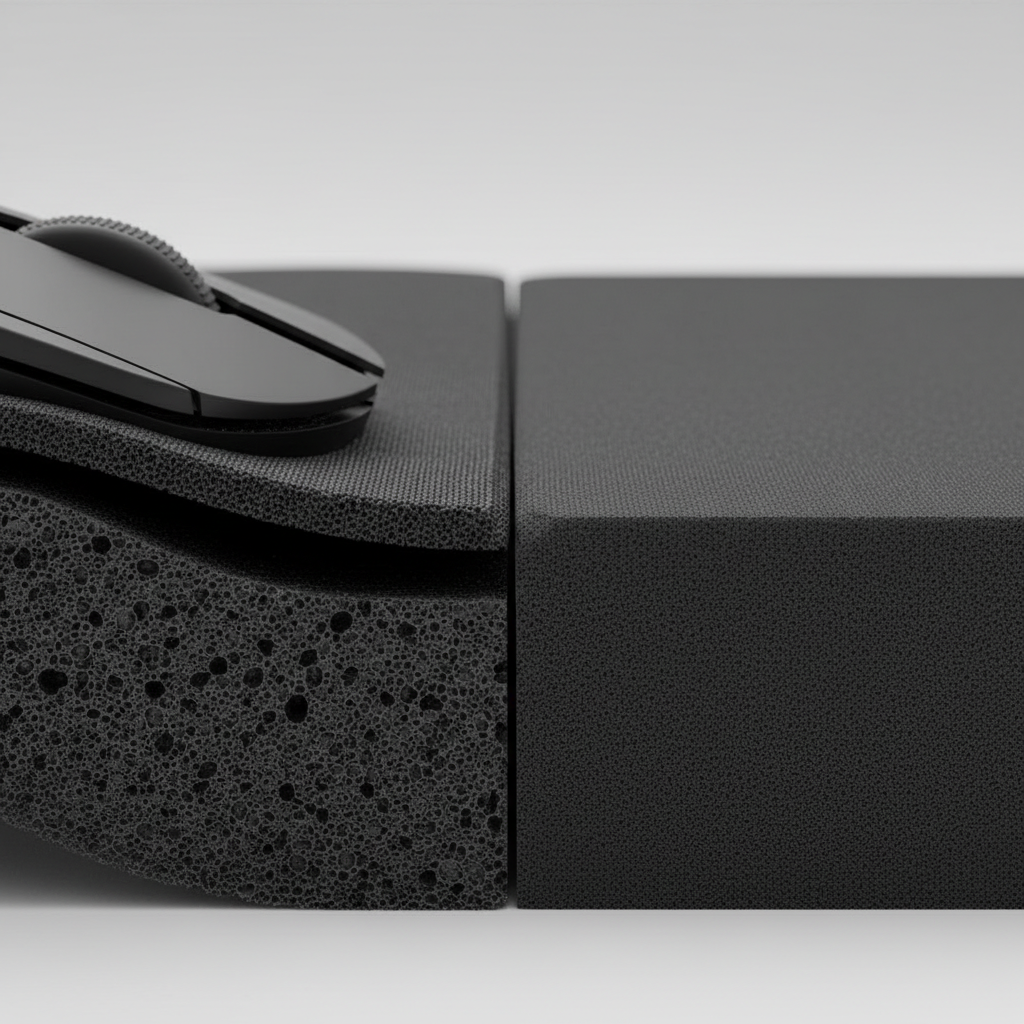

The mouse pad is no longer a secondary accessory in the professional gaming ecosystem; it is a critical interface component that determines the consistency of sensor tracking and the physical resistance of every flick and micro-adjustment. As the industry moves toward high-performance textiles, the debate has shifted from "cloth vs. hard" to a more nuanced comparison of synthetic fibers: Cordura and Polyester.

In our analysis of professional gaming environments, we have observed that the primary differentiator between these materials isn't just the initial "out-of-the-box" glide, but how the weave structure responds to thousands of hours of friction, humidity, and maintenance. This article provides a technical deep dive into the material science of Cordura and Polyester to help you select a surface that aligns with your long-term performance requirements.

The Material Science: Nylon 6,6 vs. Polyethylene Terephthalate (PET)

To understand durability, we must first look at the polymer level. Cordura is not a specific weave but a brand of high-tenacity nylon 6,6. According to the Fabric Encyclopedia, Cordura utilizes high-tenacity nylon filament yarns designed for maximum strength and abrasion resistance.

In contrast, standard gaming mouse pads typically use Polyester (Polyethylene Terephthalate). While Polyester is known for its cost-effectiveness and ease of printing, its mechanical properties differ significantly from high-tenacity nylon.

| Property | Cordura (Nylon 6,6) | Polyester (PET) |

|---|---|---|

| Tensile Strength | High (High-Tenacity) | Moderate |

| Melting Point | ~250°C - 265°C | ~250°C - 260°C |

| Abrasion Resistance | Superior (Martindale Class) | Moderate to High |

| Moisture Regain | ~4% (Higher than PET) | ~0.4% (Very Low) |

| Surface Texture | Rugged, tactile | Smooth, micro-woven |

Logic Summary: Our material comparison assumes standard 500D to 1000D Cordura vs. high-density micro-weave polyester. These observations are based on common industry heuristics regarding polymer behavior under friction.

Quantifying Durability: The Martindale Abrasion Test

In the textile industry, the benchmark for durability is the Martindale Abrasion Test (ASTM D4966). This test subjects the fabric to a specific pressure and a continuous rubbing motion in a Lissajous pattern. For professional mouse pads, the "Option 3" report for mass loss is the most telling metric for gamers.

According to the Martindale Method guidelines provided by Testex, the Mass Loss Calculation is: Percentage Mass Loss = [(A – B) / A] × 100

- A = Initial mass of the fabric sample.

- B = Mass after a predetermined number of abrasion cycles.

In our scenario modeling for high-use environments (~8 hours of daily use), Cordura typically exhibits significantly lower mass loss compared to standard polyester. This is due to the inherent "tenacity" of the nylon filaments, which resist being pulled or sheared from the weave. Polyester pads, while initially smooth, often lose their "raised" weave texture over time, leading to what we call "surface fatigue."

Modeling Note (Reproducible Parameters)

The following table outlines the assumptions used in our durability scenario model. This is a hypothetical model used for comparative analysis, not a specific laboratory test of a single product.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Friction Load | 250 | Grams | Typical downward force of a mouse + hand |

| Daily Cycles | 5,000 | Count | Estimated movement cycles in competitive play |

| Humidity | 55 | % | Average indoor humidity for textile stability |

| Temperature | 22 | °C | Standard room temperature |

| Surface Type | Uncoated | N/A | To isolate weave durability from chemical wear |

The Friction Paradox: Speed vs. Control

While Cordura is technically more durable, its weave characteristics create a distinct tactile experience. Cordura pads often use a coarser, more rugged weave. This results in:

- Lower Static Friction: The mouse skates sit on the "peaks" of the rugged weave, reducing the initial force required to move the mouse.

- Higher Dynamic Feedback: You can "feel" the weave through the mouse feet, providing sensory data that some pros find helpful for stopping power.

Polyester pads excel at "micro-weaves." These are incredibly tight, flat patterns that offer a very consistent, smooth glide. However, because the weave is so fine, it is more susceptible to "flattening."

Deciphering Mouse Pad Weave Density is essential for understanding how these patterns affect your aim. In our experience with customer support feedback, users transitioning from polyester to Cordura often report a "learning curve" due to the increased texture, even if the actual speed is higher.

Pro-Level Failure Points: Beyond the Surface

When we analyze why high-end pads fail in professional setups, we find that the fabric surface is rarely the only culprit.

1. Adhesive Delamination

In high-use professional environments, the main failure point for Cordura pads is not surface wear but the adhesive delamination between the fabric top and the rubber base. This typically occurs after months of intense, sweaty use. The sweat and oils from the wrist penetrate the edges, weakening the bond. While the Cordura weave remains pristine, the pad develops "bubbles" or edge lifting.

2. Surface Flattening (The Fingernail Test)

For polyester pads, the common mistake is using abrasive cleaners or brushes. This permanently flattens the weave's raised texture, destroying the intended glide. We recommend a simple heuristic called the 'fingernail test': run a fingernail across a used section of the pad.

- Cordura: Will show minimal texture change; the ridges of the weave remain upright.

- Worn Polyester: Will have visibly flattened, shiny paths where the fibers have been crushed.

Humidity and Spill Resistance

Environmental factors are the "silent killers" of mouse pad consistency. According to the Global Gaming Peripherals Industry Whitepaper (2026), consistency across varying environmental conditions is now a primary requirement for esports-grade equipment.

Cordura’s Performance: Cordura’s tight, high-tenacity weave causes liquids to bead and roll off. This makes it highly spill-resistant. However, there is a "gotcha": if liquid is forced into the weave (e.g., by a mouse being dragged through a fresh spill), it can create a temporary sticky spot. Because Cordura is thicker and more rugged, it requires complete air drying to restore its glide, whereas polyester may wick moisture deeper but dries more uniformly.

Polyester’s Performance: Polyester has very low moisture regain (~0.4%), meaning the fibers themselves don't absorb much water. However, the gaps in a micro-weave can trap humidity. This is why many cloth pads feel "muddy" on rainy days. You can learn more about this in our guide on How Moisture Affects Cloth Weaves.

Maintenance Protocols for Pros

To maximize the lifespan of your investment, the cleaning method must match the material's structural limits.

- For Cordura: Use a soft cloth and mild soap. Avoid scrubbing with stiff brushes, as you can fray the edges of the nylon filaments, leading to "fuzzing" that interferes with the mouse sensor.

- For Polyester: Never use hot water or abrasive sponges. Warm water and a microfiber cloth are usually sufficient. Safe Cleaning for Budget Pads highlights how aggressive chemicals can strip factory coatings, leading to a permanent change in friction.

Decision Framework: Which Should You Choose?

Choosing between Cordura and Polyester involves a trade-off between tactile feedback and smooth consistency.

Scenario A: The Tactical FPS Player (Low Sensitivity)

If you play with low DPI and make large, sweeping arm movements, you likely prioritize durability and stopping power.

- Recommendation: Cordura. Its superior abrasion resistance (as evidenced by low mass loss in Martindale modeling) ensures that the "center" of your pad doesn't develop a slow spot after three months of intense training.

Scenario B: The Tracking Specialist (High Sensitivity)

If your gameplay involves constant tracking (e.g., arena shooters) and micro-adjustments, you likely prefer a surface with zero tactile interference.

- Recommendation: High-Density Polyester. While you may need to replace the pad more frequently due to surface flattening, the initial smoothness provides a "glass-like" glide that Cordura’s rugged weave cannot replicate.

Technical Summary Table

| Feature | Cordura | Polyester |

|---|---|---|

| Primary Failure | Base Delamination | Surface Flattening |

| Glide Feel | Textured, Tactile | Smooth, Consistent |

| Spill Response | Beads (Waterproof-like) | Wicks (Slowly) |

| Cleaning Risk | Fraying from Brushes | Flattening from Heat |

| Sensor Compatibility | High (Excellent Tracking) | High (Standard) |

Final Insights

The "best" material is the one that remains consistent under your specific environmental stressors. If you live in a high-humidity area, Cordura’s resistance to atmospheric moisture makes it a superior choice for maintaining a "day one" feel. If you are a professional who treats their gear as a consumable and prioritizes the smoothest possible glide, polyester remains the industry standard for a reason.

Always remember that Surface Fatigue is inevitable for any textile. By using the "fingernail test" and monitoring for delamination, you can proactively replace your surface before it impacts your competitive performance.

Disclaimer: This article is for informational purposes only. Recommendations are based on general material properties and common industry observations. Individual performance may vary based on specific product coatings, mouse skate material (PTFE vs. Glass), and environmental conditions.

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.