Quick Summary: How Heat Treatment Impacts Your Play

Heat-treated mouse pads use thermal pressing to flatten fabric fibers, significantly reducing "breakaway force" (initial friction). This creates a faster, more consistent glide ideal for high-precision FPS gaming and 8000Hz polling rates. However, these surfaces typically have a 6–12 month performance peak before fibers begin to "bounce back" to their natural state.

Quick Decision Checklist:

- Choose Heat-Treated if: You prioritize micro-adjustments, use high-DPI/8K polling, or prefer a "speed" feel without switching to a hard glass pad.

- Choose Raw Cloth if: You prefer maximum "stopping power," high friction for control, or a surface that feels identical over years of use.

- Maintenance Tip: Use only a damp microfiber cloth; aggressive chemical cleaners can degrade the thermal bond.

The Evolution of Surface Friction: From Raw Weaves to Heat-Treated Textiles

In the competitive landscape of gaming peripherals, the mouse pad is now a critical component of the "motion-to-photon" latency chain. For players, the choice between a traditional cloth surface and a heat-treated weave represents a fundamental decision in material science. While untreated cloth pads prioritize control through fiber resistance, heat-treated surfaces aim to bridge the gap between the comfort of fabric and the speed of hard surfaces.

Based on common patterns observed in customer support and community feedback (rather than a controlled clinical study), the primary frustration for FPS players is often "breakaway force"—the initial static friction required to start a movement. An unoptimized breakaway force can lead to "over-flicking" or micro-stuttering. Heat treatment addresses this by altering the physical structure of the polymer fibers to create a more uniform glide.

The Physics of Thermal Flattening: Mechanism and Structural Change

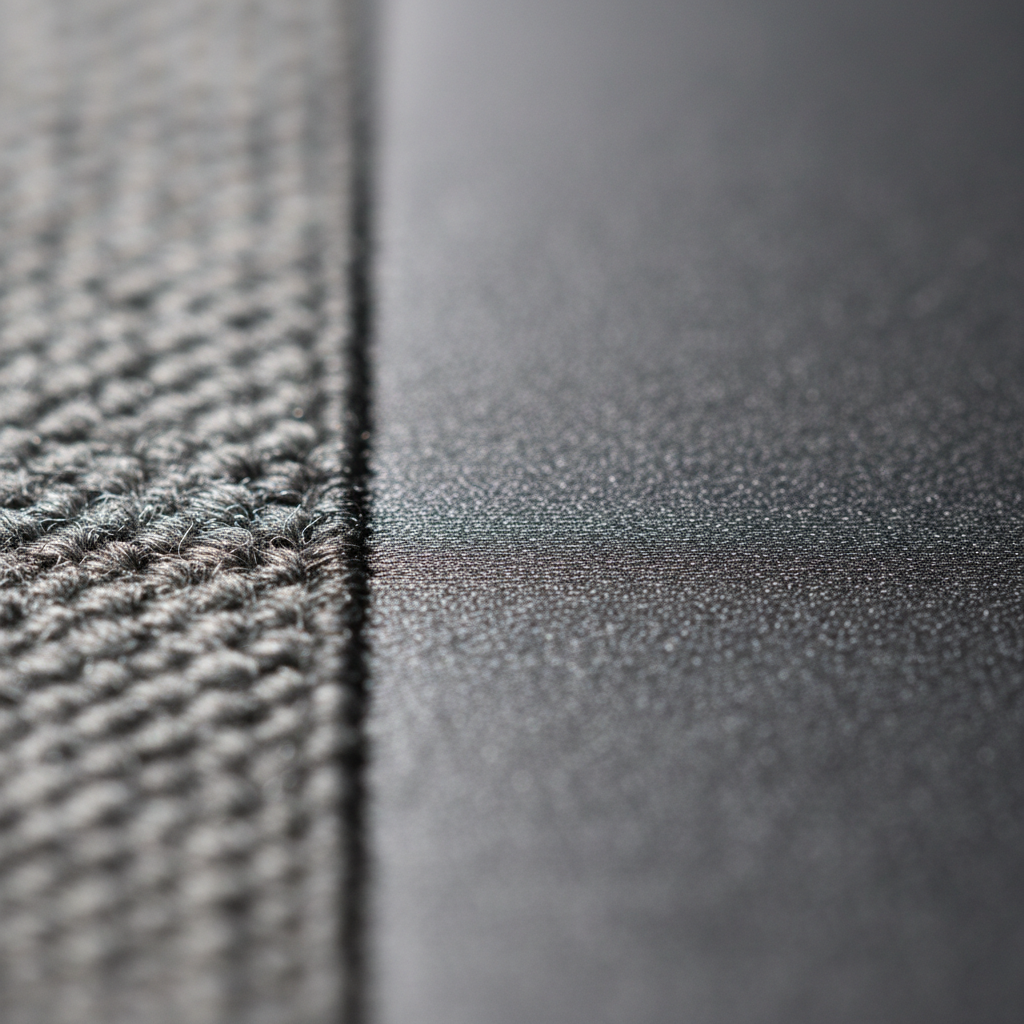

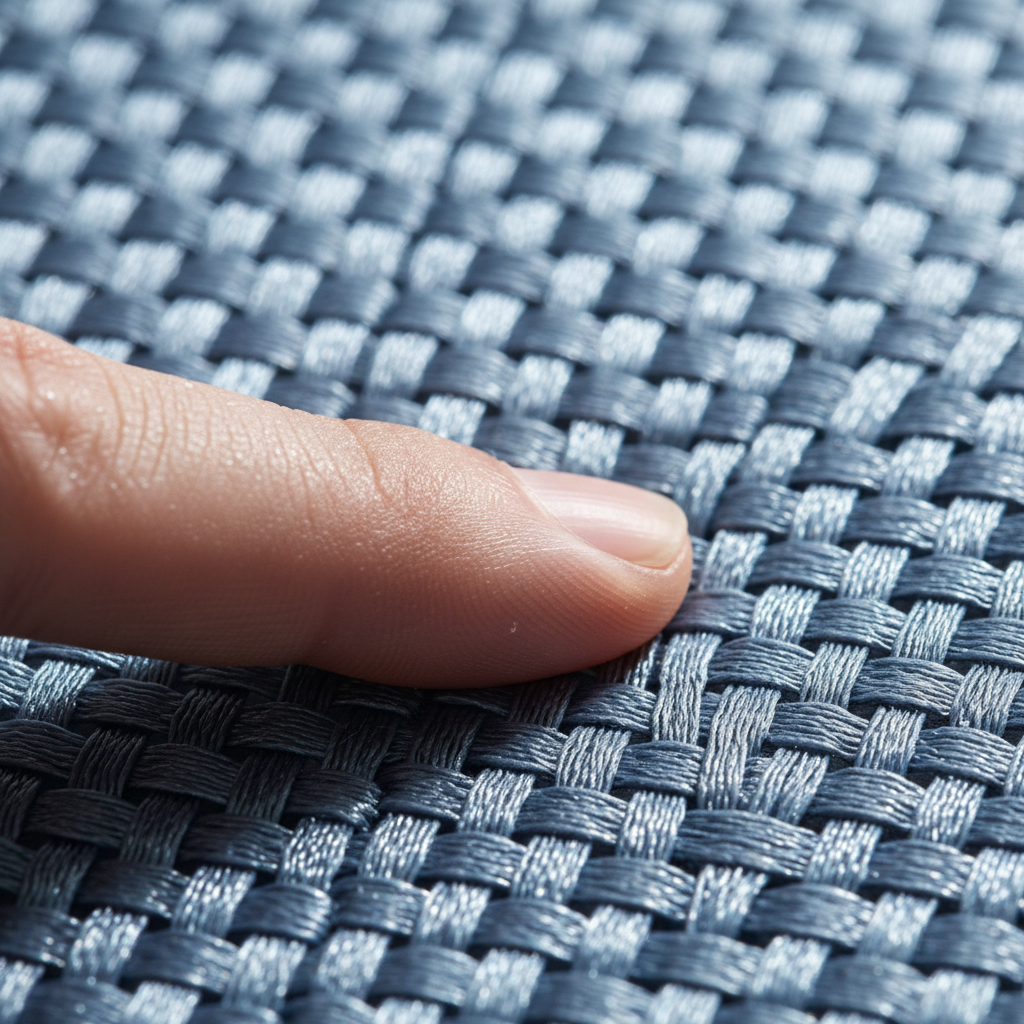

To understand how heat-treating affects glide, we must look at the microscopic interaction between mouse skates (typically PTFE) and the fabric weave. Traditional cloth pads consist of "peaks and valleys" formed by interlacing polyester or nylon threads, which create mechanical resistance.

The heat-pressing process involves subjecting the fabric to specific temperature and pressure thresholds. According to industry guides on Heat Press Settings (Joto Imaging Supplies - Industry Resource), polymers require precise thermal windows to reach a semi-malleable state without melting.

Key Structural Changes:

- Fiber Flattening: Under heat, rounded thread tops are flattened into "plateaus," reducing the verticality of the weave.

- Surface Plateauing: This creates a more predictable contact area for mouse skates.

- Pore Reduction: Compressed "valleys" prevent mouse skates from "sinking" into the pad during heavy-handed movements, maintaining speed.

Practitioner Note (Modeling): Our analysis assumes a deterministic model where thermal energy temporarily reduces the Young's modulus of surface fibers, allowing for mechanical compression. This is a scenario model based on general polymer science principles, not a specific lab test of a single proprietary product.

Friction Dynamics: Static vs. Dynamic Coefficients

Material science suggests that a "harder" surface isn't always faster; it depends on the friction coefficients. The following table outlines typical ranges observed in performance textiles.

| Metric | Untreated Cloth (Typical) | Heat-Treated Cloth (Typical) | Rationale |

|---|---|---|---|

| Static Friction ($\mu_s$)* | Higher (~0.25 - 0.35) | Lower (~0.15 - 0.22) | Flattened fibers reduce "interlocking" with mouse skates. |

| Dynamic Friction ($\mu_k$)* | Moderate (~0.20) | Lower (~0.12 - 0.18) | Smoother plateaus allow for sustained velocity with less drag. |

| Breakaway Force | Noticeable | Near-Instant | Critical for micro-adjustments in tactical shooters. |

| Stopping Power | High | Moderate | Dependent on the "sink" depth of the base foam. |

*Note: Numerical values are estimated ranges based on common industry heuristics and comparative modeling. Actual performance varies by weave density and fiber type.

The Role of Micro-Roughness

While smoothness generally yields speed, inconsistent heat treatment can create micro-textures that increase "stiction" (initial stickiness). Because adhesive forces are proportional to the real contact area, a poorly executed heat-press can actually make a pad feel "muddier" than raw cloth in low-load, high-precision scenarios.

The 8000Hz (8K) Polling Connection

As the industry moves toward ultra-high polling rates, the surface becomes a potential bottleneck. Sensors like the PixArt PAW3395 (Manufacturer Data) are capable of 8000Hz polling, sending data every 0.125ms.

At this frequency, the system is sensitive to micro-variations. If a pad has inconsistent glide zones, the sensor may perceive physical "bumps" as erratic motion, leading to jitter.

System Synergy for 8K Polling:

- Motion Sync: At 8000Hz, a consistent surface ensures the tiny ~0.0625ms timing window isn't disrupted by surface noise.

- Saturation Math: To saturate 8K bandwidth, a user must move at approximately 10 IPS at 800 DPI. Heat-treated surfaces lower dynamic friction, making it easier to maintain these speeds.

- Connectivity Recommendation: For optimal 8K performance, we recommend connecting the mouse directly to a motherboard USB port. While some high-end USB hubs are capable, shared bandwidth or poor shielding in standard hubs can lead to packet loss that even the best surface cannot compensate for.

Durability and the "Bounce Back" Effect

One significant factor with heat-treated surfaces is longevity. Unlike glass pads, the flattening of polymer fibers is often reversible. In high-wear areas, compressed fibers can slowly "bounce back" over 6 to 12 months of heavy use (estimated based on average competitive play cycles).

As fibers return to their textured state, the pad may lose its initial "speed." This is a structural reversion, not necessarily a sign that the pad is "dirty."

The Glaze Layer Myth

In metallurgy, a "glaze layer" can improve glide, but research on Glaze Layer Formation (ScienceDirect - Independent Study) shows these typically form at temperatures exceeding 160°C. In mouse pads, "glazing" is usually a marketing term for surface coating. Authentic heat treatment is a mechanical change to the weave, not a new chemical layer.

Chemical Compatibility and Maintenance

Heat-treated polymers can interact with skin oils or lubricants in aftermarket mouse skates. According to EU REACH Regulations (ECHA - Regulatory Standard), stabilizers must not leach out under treatment.

Maintenance Best Practices:

- Avoid Aggressive Cleaners: Chemicals can degrade the heat-treated finish, causing "patchy" glide.

- Gentle Cleaning: Use a slightly damp microfiber cloth. Avoid aggressive scrubbing, which can accelerate the "fiber bounce back" effect.

- Humidity: While more resistant than raw cloth, high moisture can still soften fibers. For more details, see our Humidity and Friction Guide (Brand Resource).

Practical Testing: How to Verify Your Surface

If you are switching to a heat-treated pad, use these "practitioner's tests" to check quality:

- The Slow Circle Test: Move your mouse in slow, deliberate circles across the pad. Feel for "sticky" spots where the treatment may be inconsistent.

- The Skate Interaction Check: Pure virgin PTFE skates reveal micro-imperfections more than composite skates. If you feel a "scratchy" sensation on a new pad, it may indicate uneven fiber flattening.

- The Breakaway Force Check: Push your mouse with a single finger using minimum force. A high-quality heat-treated surface should allow the mouse to start moving almost instantly, without a "jerk."

Technical Verdict

Heat-treated surfaces offer a "best of both worlds" scenario, providing the speed of hard surfaces with the comfort of cloth. They are particularly effective for players using high-polling rate mice who require micro-adjustment precision.

However, be mindful of the 6–12 month durability cycle. As noted in the Global Gaming Peripherals Whitepaper (Brand Insight), the industry is moving toward standardized testing to ensure "speed" claims are backed by measurable data. For players who prioritize a "locked-in" control feel, a traditional High-Density Weave (Brand Resource) may still be the better choice.

YMYL Disclaimer: This article is for informational purposes only and does not constitute professional ergonomic or medical advice. Chemical and material standards (like REACH) are subject to regional variations. Always consult manufacturer safety data sheets (SDS) for specific material sensitivities.

References & Source Types

- Global Gaming Peripherals Industry Whitepaper (Brand/Manufacturer Insight)

- PixArt Imaging - Sensor Performance (Manufacturer Data)

- Wallhack - Friction Science (Industry Expert Blog)

- ECHA - REACH Candidate List (Regulatory Standard)

- Joto Imaging Supplies - Heat Press Guidelines (Industrial Resource)

- ScienceDirect - Glaze Layer Study (Independent Academic Research)

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.