In the precision-driven world of mechanical peripherals, the reliability of a keystroke is often taken for granted. However, for enthusiasts and professional gamers, the phenomenon known as "key chatter"—where a single press registers as multiple inputs—remains a persistent technical frustration. While many users attribute this to software glitches or dust, the root cause is fundamentally metallurgical. To address the "Specification Credibility Gap" in value-oriented high-performance gear, we must examine the material science behind leaf spring construction and the engineering required to maintain electrical signal integrity over 100 million actuations.

According to the Global Gaming Peripherals Industry Whitepaper (2026), the industry is shifting toward more rigorous material validation to meet the demands of high-polling-rate environments. As polling rates climb to 8000Hz (0.125ms intervals), the margin for error in electrical contact stability has effectively vanished.

The Physics of Contact Chatter: Resonance and Elasticity

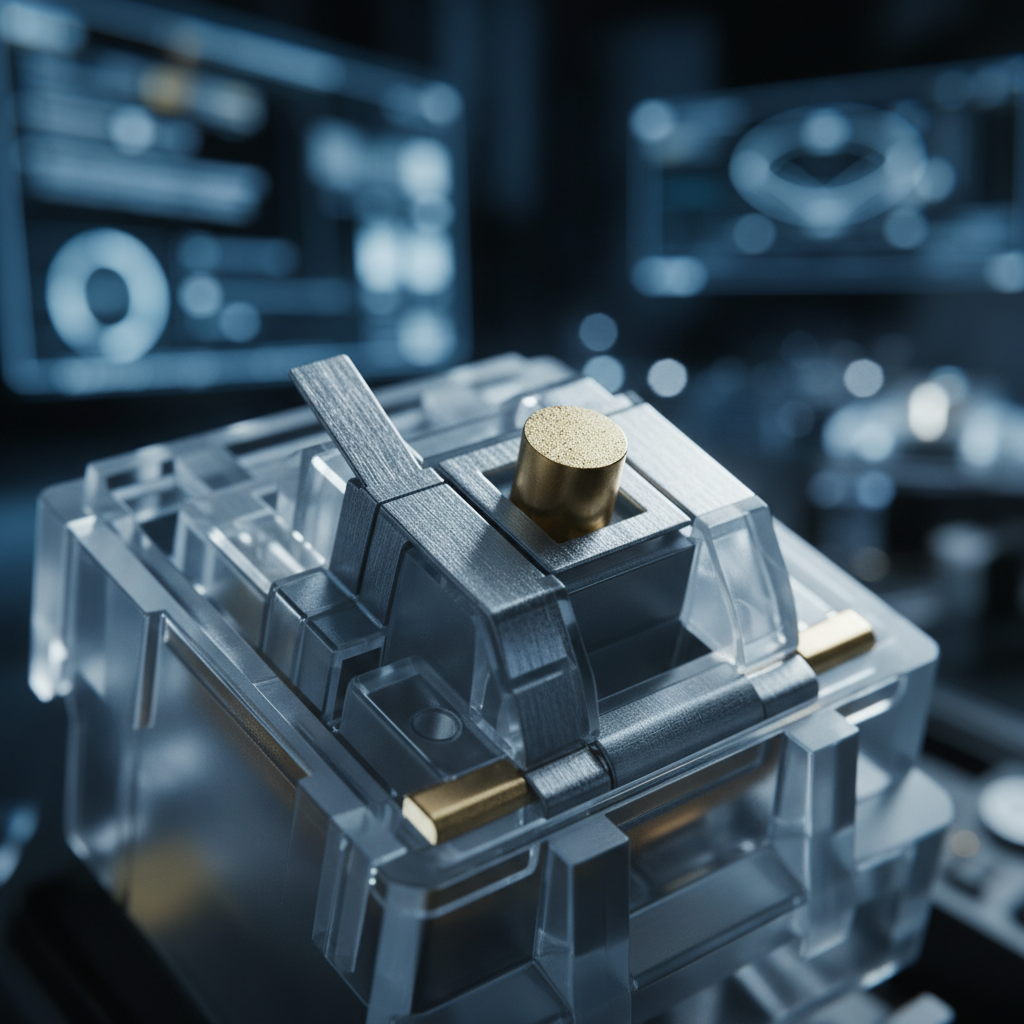

Key chatter is not merely a mechanical failure; it is a manifestation of resonant instability. When a switch is actuated, the leaf spring—a thin, conductive metal component—is forced into contact with a stationary terminal. This collision induces vibrations. If the material's damping properties are insufficient, the spring will "bounce" off the terminal several times before coming to a rest.

Contrary to conventional wisdom, which suggests that high inter-leaf friction is the primary defense against chatter, research indicates that excessive friction can actually mask root causes or shift the system into damaging resonant modes. Research on steel components, such as CF53, shows that the critical metallurgical property is the material's elastic modulus and density, which directly determine the spring's natural frequency. By optimizing the geometry and mass of the leaf, engineers can ensure that natural frequencies remain distant from the excitation frequencies generated during rapid typing or gaming.

Gold-Crosspoint Technology: The 3-Micron Standard

The most effective mechanism for preventing oxidation and ensuring low contact resistance is the application of gold-crosspoint technology. However, not all gold plating is created equal. A common industry pitfall is specifying "gold-plated" contacts without defining the plating thickness or purity.

For a switch to survive 50 million to 100 million actuations without signal degradation, a minimum of 3-5 microns of 24k gold or a hard gold alloy (such as cobalt-hardened gold) is required. Thinner coatings, often measured in mere micro-inches, can wear through within the first year of heavy use, especially in humid environments. Once the gold layer is compromised, the underlying nickel or copper alloys are exposed to atmospheric oxygen, leading to the formation of non-conductive oxides. This oxidation layer is the primary driver of "chatter" in aged switches.

The geometry of the contact point is equally critical. A rounded, polished crosspoint creates a consistent "wiping action" during actuation. This action helps clear microscopic debris and ensures a fresh contact surface with every press, significantly reducing the likelihood of signal noise.

Material Selection: Copper Alloys and Damping

The base metal of the leaf spring is typically a copper-based alloy chosen for its electrical conductivity and fatigue resistance. However, the interaction between this metal and the switch housing can introduce unpredictable wear.

| Material Property | High-Spec Copper Alloy | Standard Brass | Impact on Performance |

|---|---|---|---|

| Electrical Conductivity | >90% IACS | ~25-28% IACS | Lower heat generation, cleaner signal |

| Elastic Modulus | 110-130 GPa | 100-110 GPa | Higher frequency stability |

| Fatigue Life | 100M+ Cycles | <50M Cycles | Long-term reliability |

| Corrosion Resistance | High (with Ni/Au) | Moderate | Prevents chatter-inducing oxides |

While metallurgy is the focus, the industry often utilizes polymer liners (e.g., Nylon) to eliminate metal-on-metal friction within the switch housing. As explored in our analysis of Nylon vs. Polycarbonate, these materials provide the necessary damping to suppress chatter at its source, revealing that material science in keyboards is a multi-layered discipline involving both metals and polymers.

Environmental Stress and Signal Integrity

Real-world implementation of high-performance switches must account for environmental variables. Accelerated lifecycle testing has shown that even well-plated contacts can fail prematurely if the switch housing does not provide an adequate seal against dust and humidity. Particulates can act as abrasives, accelerating the wear of the gold plating and increasing the coefficient of friction (COF).

In high-humidity regions, the risk of "fretting corrosion"—small-scale movements that wear away the protective coating—is amplified. To combat this, premium switches often undergo environmental stress testing as part of their compliance with international standards. For instance, devices seeking FCC Equipment Authorization or ISED Canada Radio Equipment List (REL) certification must demonstrate stability under various electromagnetic and environmental conditions to ensure they do not produce unintended interference or fail in a way that compromises safety.

Advanced Testing: Beyond the Binary "On/Off"

True expertise in switch engineering involves monitoring the rise time and stability of the electrical signal. Using tools like the NVIDIA Reflex Analyzer, engineers can measure the "click-to-photon" latency, but the internal "debounce time" is where metallurgical quality is proven.

An increase in signal bounce time—the duration it takes for a signal to stabilize after contact—is the first indicator of impending failure. While modern firmware can filter out this noise (a process called debouncing), excessive debounce filters increase input lag. By using high-purity gold alloys and optimized leaf geometry, the physical bounce time can be kept below 1ms, allowing for the ultra-low latency required by competitive gamers.

For those looking to maximize their setup's performance, accessories like the ATTACK SHARK C04-C COILED CABLE ensure that the high-quality signal generated by the switches is transmitted without loss. The use of a 5-pin aviator connector and high-quality TPU shielding prevents external EMI from injecting noise into the already delicate timing of a high-polling-rate device.

Scenario Analysis: Standard Use vs. Extreme Environments

The requirements for leaf spring metallurgy vary significantly based on the user's environment and performance needs.

Scenario A: The Standard Home/Office Setup In a climate-controlled environment with moderate usage (2-4 hours a day), a standard gold-flashed contact (approx. 1 micron) is often sufficient. The risk of chatter is low, and the primary concern is the acoustic profile of the switch. For these users, aesthetic upgrades like the ATTACK SHARK 120 Keys PBT Dye-Sublimation Pudding Keycaps Set provide more immediate value than extreme metallurgical hardening.

Scenario B: The Competitive Esports/High-Humidity Environment For users in tropical climates or professional players actuating keys thousands of times per hour, the 3-5 micron gold plating becomes a necessity. In these cases, the high polling rates of devices like the ATTACK SHARK X8PRO Ultra-Light Wireless Gaming Mouse & C06ULTRA Cable demand perfection. When running at 8000Hz, the system processes a packet every 0.125ms. Any metallurgical instability that causes a signal bounce longer than this interval will result in dropped packets or jitter, directly impacting competitive performance.

Regulatory Compliance and Material Safety

Beyond performance, the materials used in switches must adhere to strict safety and environmental regulations. The ECHA Candidate List of Substances of Very High Concern (SVHC) under the REACH regulation ensures that harmful chemicals are not used in the manufacturing of keycaps or switch housings. Furthermore, the EU RoHS Directive restricts the use of lead and other heavy metals in the solder and leaf spring alloys, ensuring that the peripherals are safe for long-term contact and environmentally responsible disposal.

For wireless devices, such as the ATTACK SHARK X8 Series Tri-mode Lightweight Wireless Gaming Mouse, compliance with the EU Radio Equipment Directive (RED) is mandatory. This directive ensures that the high-frequency signals used for 2.4GHz wireless and Bluetooth do not interfere with other critical infrastructure, a requirement that is increasingly difficult to meet as polling rates and data densities increase.

Engineering for Longevity

The transition from a "budget" perception to a "professional" standard requires a commitment to the invisible details of material science. By prioritizing 3-5 micron gold plating, rounded crosspoint geometries, and high-elastic-modulus alloys, a brand can eliminate the root causes of chatter and provide a level of reliability that matches the highest industry benchmarks.

As we continue to push the boundaries of peripheral technology, the focus must remain on the fundamental mechanisms of electrical contact. Whether it is through the implementation of Rapid Trigger Mechanics or the refinement of traditional leaf spring metallurgy, the goal remains the same: a perfect, singular registration for every single press.

Disclaimer: This article is for informational purposes only. While technical specifications are based on industry standards and engineering principles, individual product performance may vary based on usage patterns and environmental conditions. Always refer to the manufacturer's technical documentation for specific maintenance and safety guidelines.

Sources

- Global Gaming Peripherals Industry Whitepaper (2026)

- FCC Equipment Authorization (FCC ID Search)

- European Chemicals Agency (ECHA) - SVHC Candidate List

- IEC 62368-1: Audio/video, information and communication technology equipment - Part 1: Safety requirements

- NVIDIA Reflex Analyzer Technical Documentation

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.