The Specification Credibility Gap: Why Hardware Precision Evolves

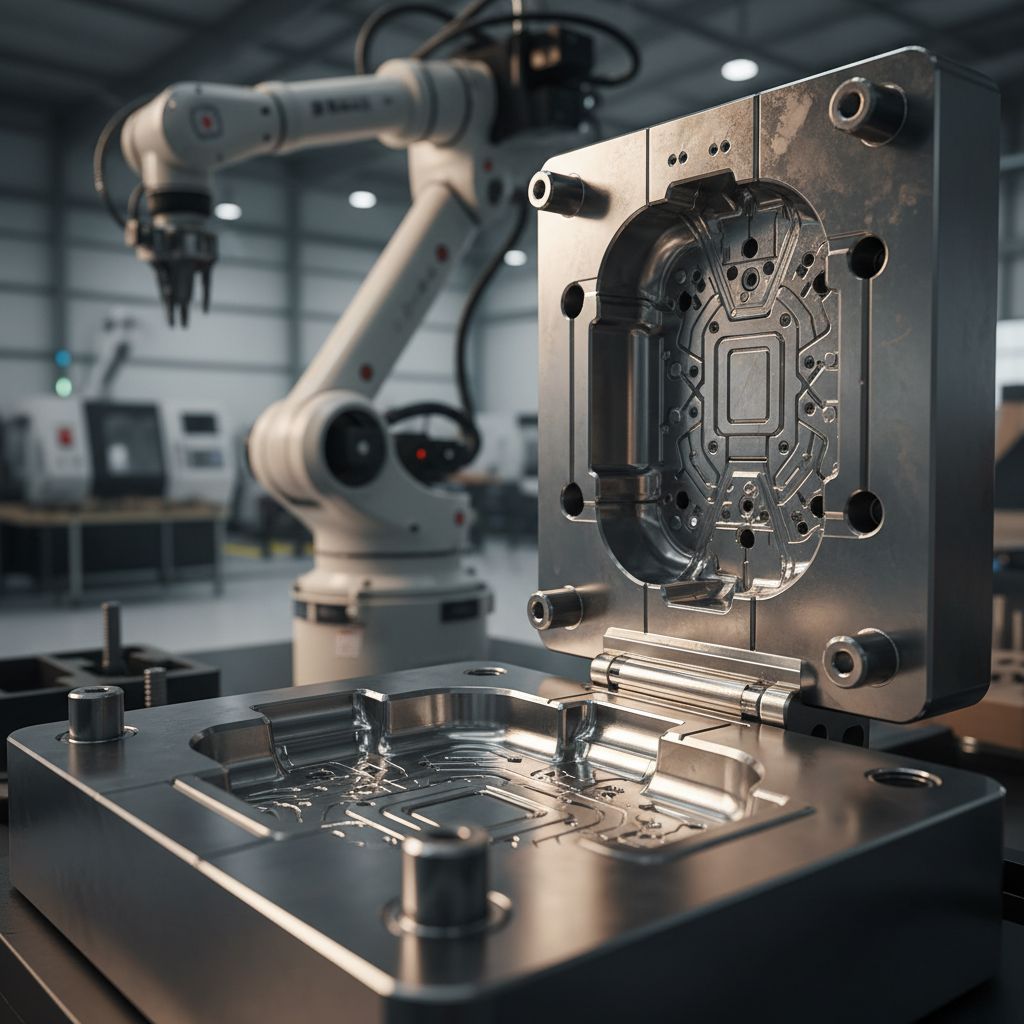

In the competitive gaming peripheral market, a "Specification Credibility Gap" often exists between a product's advertised technical specs and the actual tactile experience of the user. While two mice may both feature a high-performance PixArt PAW3395 sensor and an 8000Hz polling rate, they may feel vastly different in hand. This variance is frequently attributed to the "mold lifecycle"—the industrial reality of how injection molding tools degrade over hundreds of thousands of production cycles.

Understanding this lifecycle is critical for performance-conscious gamers who notice subtle changes in texture, button pre-travel, or shell rigidity. This article explores the technical mechanisms of mold wear and how proactive manufacturing standards, such as those detailed in the Global Gaming Peripherals Industry Whitepaper (2026), attempt to bridge the gap between theoretical specs and batch-to-batch consistency.

The Physics of Injection Molding and the S-Curve of Degradation

Most gaming peripherals use high-grade steel molds to produce ABS or PBT plastic shells. These tools are subjected to extreme pressures (often exceeding 10,000 PSI) and temperature fluctuations during every cycle. Contrary to the assumption that a mold produces identical parts until it breaks, tooling quality follows a predictable "S-curve" degradation pattern.

- Early Precision (0–50,000 Cycles): The mold surfaces are at their sharpest. Tolerances are tightest, but parts may occasionally exhibit "stiction" or minor assembly friction as surfaces have not yet "worn in."

- Optimal Maturity (50,000–150,000 Cycles): The tool has stabilized. Thermal expansion is predictable, and functional clearances have reached a "sweet spot" for ergonomic comfort.

- Late-Batch Degradation (200,000+ Cycles): Micro-abrasions from the plastic flow (especially with glass-filled or textured polymers) begin to erode the tool's core and cavity blocks.

Logic Summary: Tooling engineers track these cycles religiously because a high-volume shell mold might see 200,000+ cycles before a major refurbishment. We estimate that ergonomic integrity is highest during the "Maturity" phase, based on common industry heuristics regarding steel fatigue and thermal cycling.

Surface Roughness (Ra) and the Tactile Perception Threshold

One of the first signs of mold wear isn't dimensional; it is a loss of surface polish in textured areas. This is measured via Surface Roughness (Ra). According to technical resources on surface roughness and tactile perception, human fingertips are incredibly sensitive, capable of detecting Ra differences as low as 0.05μm on textured surfaces.

| Production Stage | Estimated Ra Value | Tactile Perception | Friction Coefficient (μ) |

|---|---|---|---|

| New Tool (Polished) | 0.1μm | "Silk-like," smooth | 0.2 |

| Mid-Lifecycle | 0.3μm | "Satin," standard grip | 0.3 |

| Late-Batch (Worn) | 0.8μm | "Gritty," uneven | 0.5 |

As the mold surface degrades, the friction coefficient increases. For a gamer using a high-performance mouse, this change in "drag" on the side grips can subtly alter their aim consistency. Proactive shops often schedule cosmetic surface polishing every 50,000 cycles to maintain Ra values within a ±10% tolerance band.

To mitigate surface-level inconsistencies, many professionals opt for high-stability surfaces. For example, the ATTACK SHARK CM04 Genuine Carbon Fiber eSport Gaming Mousepad uses genuine dry carbon fiber, which provides a consistent X/Y axis tracking surface that does not rely on the variable texture of a molded plastic desk mat.

Dimensional Drift: Button Posts and Clearance Tolerances

While surface texture affects grip, "dimensional drift" affects performance. In gaming mice, the clearance between the internal button post and the microswitch plunger is a critical dimension.

Industry data suggests that a drift of even 0.05mm (roughly half the thickness of a human hair) can significantly change the actuation feel. In late-batch units, "flash"—thin wisps of plastic on parting lines—indicates that the mold's shut-off surfaces have worn down. This can lead to:

- Increased Pre-travel: The button feels "mushy" before the click engages.

- Post-travel Variance: The button travels further than intended after actuation.

- Creaks and Groans: As clearances widen, the internal structural ribs of the shell may rub against each other.

To combat this, advanced manufacturers implement Statistical Process Control (SPC) on critical dimensions. According to Injection Mold Popper, re-cutting core and cavity blocks after 300,000 cycles is a common heuristic to maintain the ergonomic integrity required for competitive play.

The Performance Impact: Latency and Ergonomic Strain

For the "Competitive Esports Professional," these manufacturing nuances translate into measurable performance deltas. A late-batch unit with inconsistent button clearance can disrupt the timing of frame-perfect inputs, especially when utilizing high-end technologies like 8000Hz (8K) polling.

8K Polling and System Bottlenecks

At an 8000Hz polling rate, the mouse sends a packet every 0.125ms. To maintain this cadence, the system must avoid IRQ (Interrupt Request) processing bottlenecks. We strongly recommend connecting high-polling devices directly to Rear Motherboard I/O Ports to ensure maximum signal integrity and avoid the packet loss common with front-panel headers or USB hubs.

Furthermore, features like Motion Sync introduce a deterministic latency penalty. At 8000Hz, this penalty is approximately 0.06ms (half the polling interval). While negligible for most, a professional gamer may disable it to shave off every possible microsecond, making the physical consistency of the mouse's mechanical switches even more vital.

Ergonomic Modeling and the Strain Index

Mechanical inconsistency doesn't just affect aim; it affects health. We modeled a high-intensity gaming scenario using the Moore-Garg Strain Index to evaluate the risk of distal upper extremity disorders.

Modeling Note (Reproducible Parameters):

- Model Type: Deterministic Multiplicative Model (Moore-Garg SI).

- Scenario: Competitive FPS player, 4–6 hours/day, high Actions Per Minute (APM).

Parameter Value Rationale Intensity Multiplier 2.0 Rapid clicking/tension Efforts Per Minute 4.0 300+ APM Posture Multiplier 2.0 Common "claw" grip tension Duration Per Day 1.5 4+ hours of play Computed SI Score 48.0 Category: Hazardous (SI > 5) Boundary Conditions: This model assumes high-intensity repetitive motion without adequate rest intervals. It is a screening tool, not a medical diagnosis.

To mitigate this hazardous strain, users often employ ergonomic supports. The ATTACK SHARK 87 KEYS ACRYLIC WRIST REST or the ATTACK SHARK Cloud Keyboard Wrist Rest can help elevate the wrist to a more neutral position, reducing the multiplicative effect of the "Posture Multiplier" in the strain index calculation.

The "Wear-In" Counter-Consensus: When Middle Batches Win

It is a common misconception that the very first unit off the line is the "best." Experienced manufacturing engineers often observe a "wear-in" period. In this phase, initial tight tolerances relax slightly to their optimal functional clearances.

A middle-batch unit (e.g., cycle 75,000) may actually exhibit smoother actuation than a "Cycle 1" unit, which might suffer from minor mold release residue or overly sharp edges that cause internal friction. This creates a complex quality curve rather than a simple linear decline.

| Batch Phase | Mechanical Characteristic | User Experience |

|---|---|---|

| Early (1–10k) | Ultra-tight, sharp edges | Potentially "stiff" or "scratchy" |

| Middle (50k–125k) | Smoothed interfaces | "Broken-in," optimal smoothness |

| Late (200k+) | Widened clearances | "Loose," potential for shell creak |

Identifying Late-Batch Units: A Troubleshooter’s Checklist

If you are skeptical of a peripheral's consistency, look for these "late-batch" indicators:

- Parting Line Flash: Look for thin plastic "wings" where the two halves of the shell meet. This suggests the mold is no longer closing perfectly flush.

- Texture "Hotspots": Check if the matte finish is shinier in some areas than others (excluding natural oil from your skin). This indicates uneven mold polish wear.

- Button Post "Wobble": Gently wiggle the main mouse buttons side-to-side. Excessive lateral play often stems from worn guide pins in the mold.

- Actuation Variance: Use a tool like the NVIDIA Reflex Analyzer to check for click-to-photon latency consistency. While primarily a firmware test, mechanical variance in the switch plunger can cause erratic results.

Bridging the Gap through Maintenance

The "Specification Credibility Gap" is not an inevitability; it is a management challenge. Manufacturers who prioritize consistency implement structured maintenance intervals. By re-polishing every 50k cycles and re-cutting blocks at 300k, a brand can ensure that the unit purchased a year after launch feels nearly identical to the one reviewed by tech influencers on day one.

For the gamer, the takeaway is clear: specs tell you what the hardware can do, but understanding the mold lifecycle tells you how it will feel. By choosing brands that are transparent about their manufacturing quality control—and by supporting those choices with ergonomic tools and high-stability surfaces—you can maintain a competitive edge regardless of production timing.

Ergonomics & Safety Disclaimer: The information provided in this article, including the Moore-Garg Strain Index modeling, is for informational and educational purposes only. It is not intended as a substitute for professional medical advice, diagnosis, or treatment. Gaming for extended periods carries inherent risks of repetitive strain injuries. If you experience persistent pain, numbness, or tingling in your hands, wrists, or arms, please consult a qualified healthcare professional or physiotherapist.

Modeling Transparency (Reference Data): Our Motion Sync latency trade-off estimator for 8000Hz polling assumes a baseline latency of 0.8ms and an added deterministic delay of 0.0625ms (0.5 * polling interval). Runtime estimates for 8K wireless mice (300mAh battery) suggest approximately 13–15 hours of continuous use at 4000Hz, which may decrease by 75–80% when moving from 1000Hz to 8000Hz due to increased MCU and radio current draw (Source: Nordic nRF52840 Datasheet).

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.